China belleville disc spring Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our enhancement strategy for belleville disc spring,spring washers,belleville washer,belleville spring washers,disc spring washer, In our efforts, we already have many shops in China and our products have won praise from customers worldwide. Welcome new and old customers to contact us for the future long term business relationships.

belleville disc spring, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we're about to create"the reputable international brand of nylon monofilaments", and spreading our solutions to every corner of the world. We've been keep moving and try our best to serve our customers.

Hot Products

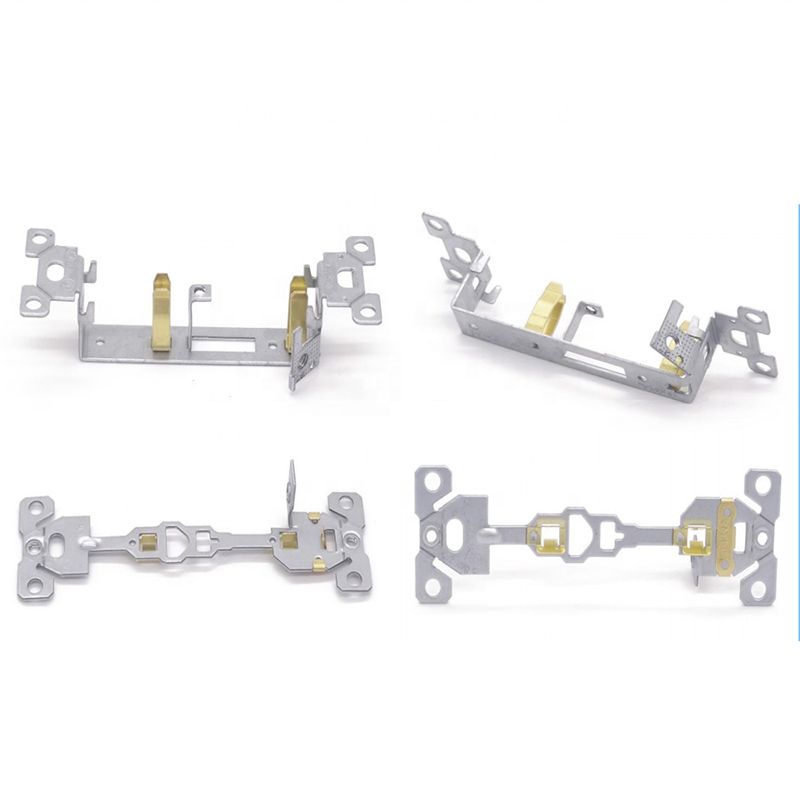

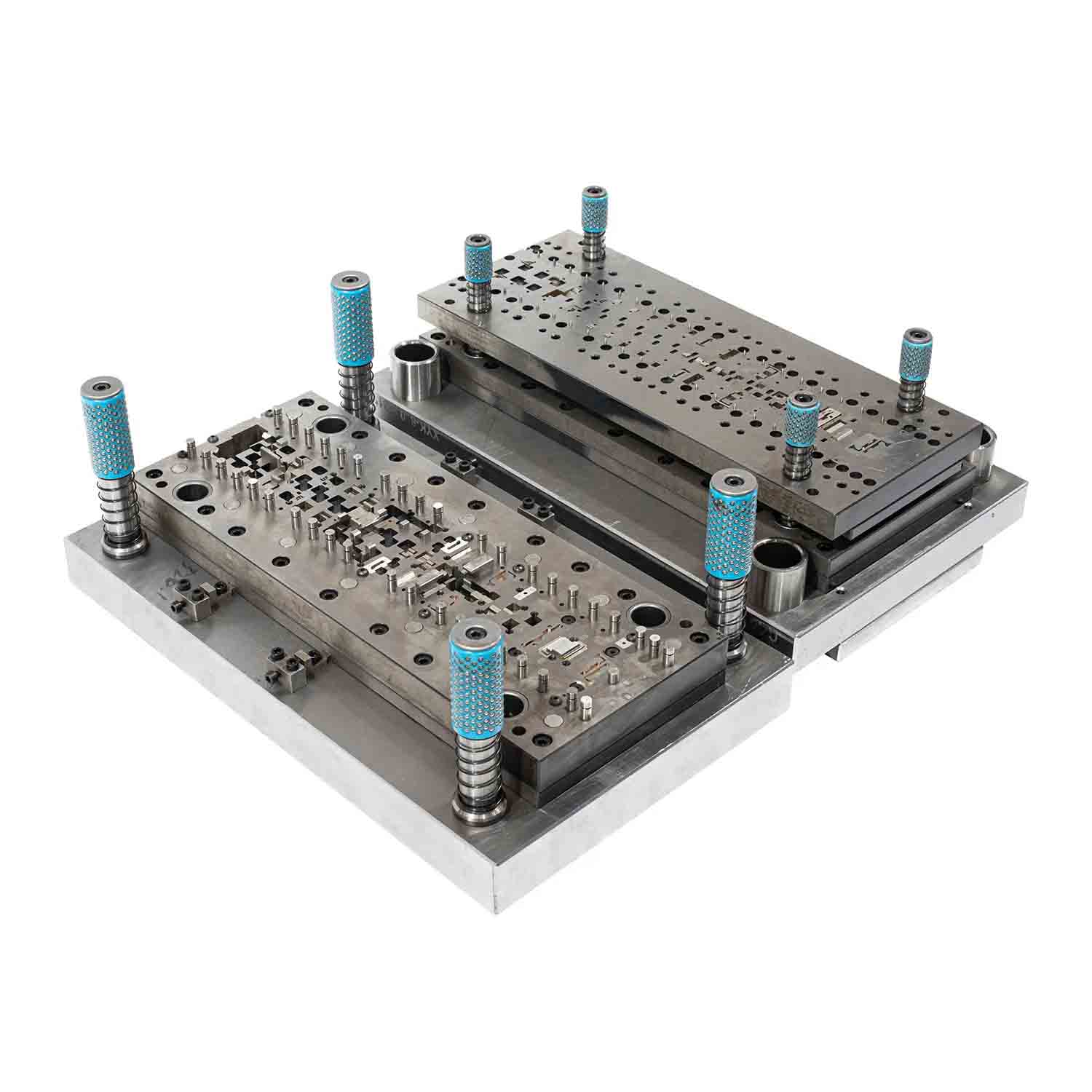

Custom Metal Stamping Dies

Xiamen Jiangjun Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.Car Seat Frame

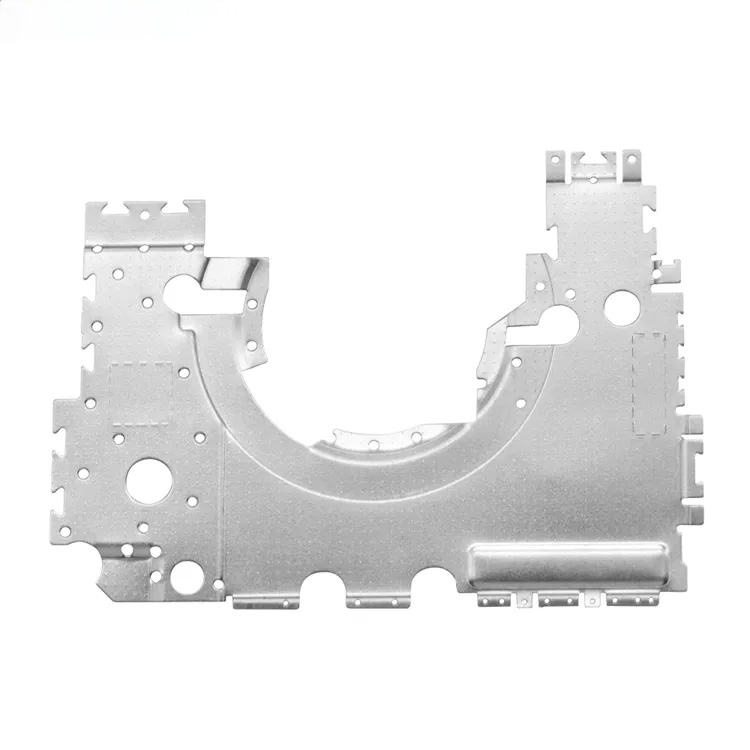

The die-cast Car Seat Frame produced by Xiamen Jiangjun Intelligent Technology Co., Ltd. is a high-quality die-cast product that can provide stable skeleton support for car seats, effectively protect the safety of passengers during driving, and also provide a more comfortable use experience for car seats. In the production process, HY uses the most advanced die-casting technology and selects high-quality raw materials to ensure the quality and performance of each product, making it your safe and comfortable seat choice.

Type: Car Seat Frame

Material: Cast iron, steel, special alloys support customization

Application scenarios: SUV/Multi-purpose passenger car/RV/camper/caravan/caravan/car trailermedical wheelchair

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in the production and supply of high-quality medical care products. HY has established a good reputation through high-quality and professional production, quality control and customer service. We provide a variety of hospital or home care products, including wheelchairs, trolleys, bathroom series, walkers, crutches and beds, etc.

Product type: medical wheelchair

Material: carbon steel, aluminum alloy, stainless steel, carbon fiber

Processing method: precision stamping

Load limit: 136KG

Recommended population: patients with impaired walking function, the elderly, patients in rehabilitation periodGas Stove Bracket

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove bracket from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperatureDie Casting Main Housing

At HY, we ensure high-speed production of Die Casting Main Housing in a wide range of sizes, shapes and configurations.Jiangjun is a first-class manufacturer and supplier in the Die Casting Main Housing.Motor Cooling Fan Blade

Motor cooling fan blade material: aluminum, Manufacturing process: die casting, Surface treatment: anodizing, powder coating, Application industry: industrial machinery, Die casting time: 100 pieces/hour,