stainless steel rivets

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of all kinds of stainless steel rivets, blind rivets, rivet nuts, pressure rivets, national standard fasteners, non-standard fasteners, and riveting tools. The company has a complete set of advanced production equipment and automatic lathes, and adopts international advanced standards for production. "Zero defects, create brands" is HY's purpose. We hope to establish a good cooperative relationship with domestic and foreign customers on the basis of equality, mutual benefit and common development.

Surface treatment: natural, black, galvanized, other

Material: stainless steel, aluminum, brass, special alloy

Processing technology: stamping

Send Inquiry

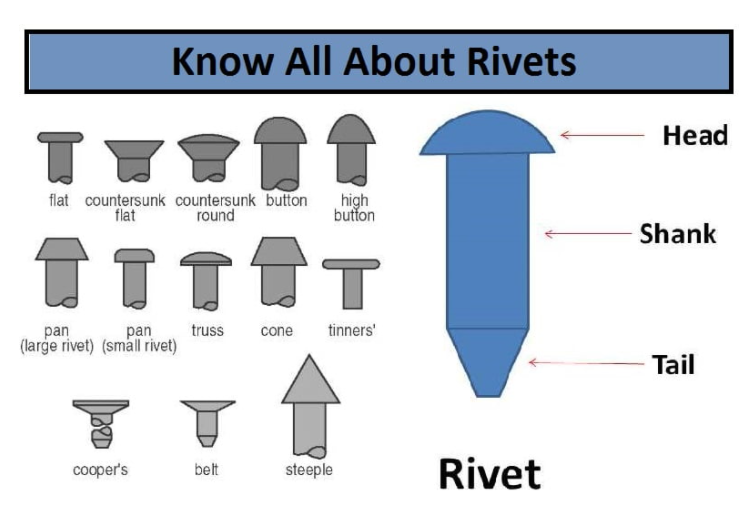

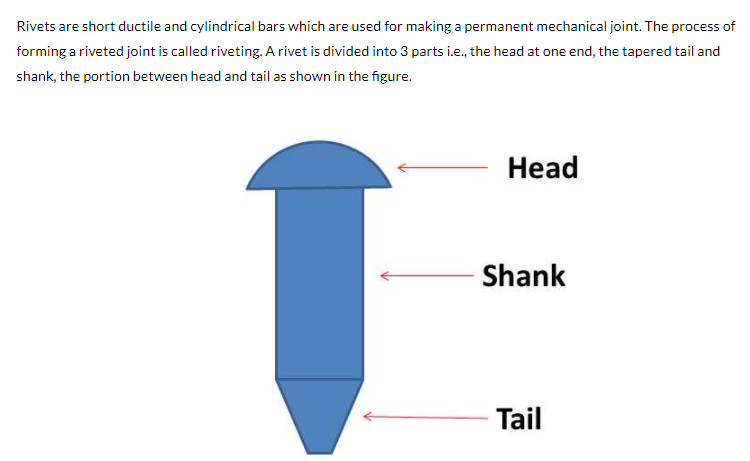

Rivet type

The early riveting process was single and the structure was simple. The rivet consists of a smooth cylindrical shaft with a head at one end. When installing, the rivet is placed in a punched or drilled hole, and the tail is thickened or bent (to deform it) to expand and fix the rivet in place.

Since the installed rivet has an effective head at each end, it can withstand tensile loads and shear loads.

In recent years, the types of stainless steel rivets processes have been enriched and the classification methods have been diverse. According to the process classification, it can be divided into cold riveting and hot riveting. According to the environmental openness requirements, it can be divided into single-sided riveting and double-sided riveting.

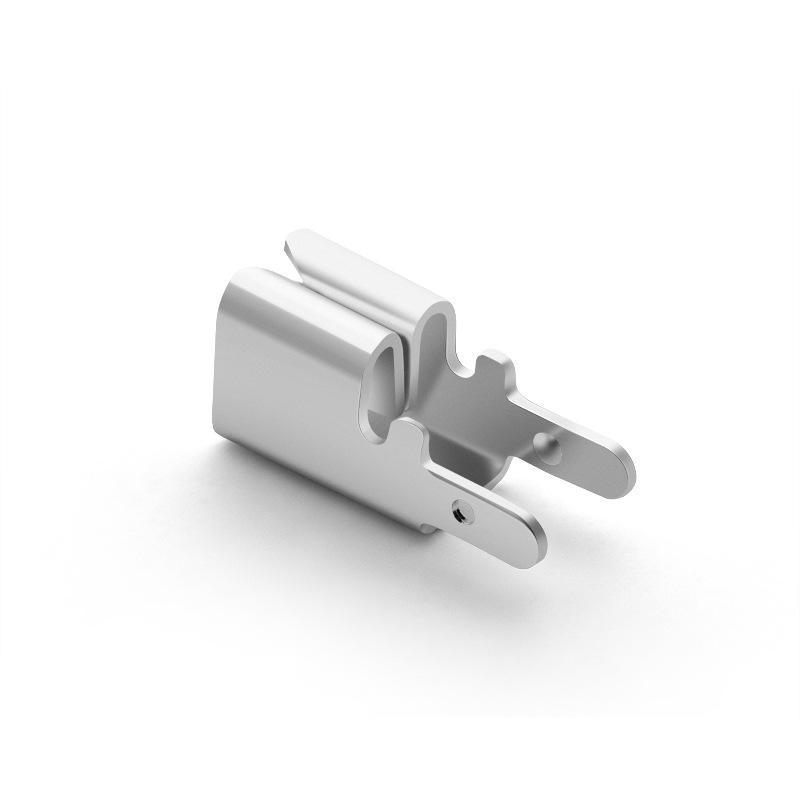

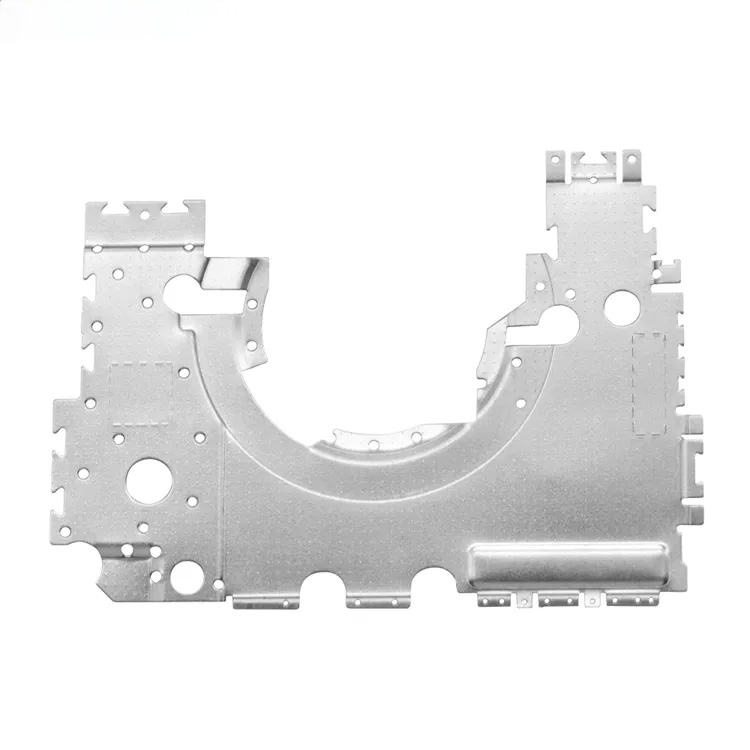

Characteristics of stamping rivets

Punch riveting is also called press riveting process. The parts are linked by plastic deformation of rivets or parts after being stressed. Whether it is rivet deformation or material deformation, the press riveting process is a cold heading process.

The punching riveting process is subjected to force quickly and the riveting efficiency is high. The connecting materials at the riveting point are inlaid with each other, and there are no edges or burrs at the bottom, which avoids stress concentration and can withstand high dynamic loads.

There is no heat input during the connection process, and the surface coating of the material at the connection point will not be damaged. At the same time, welding spatter and welding deformation are avoided, and the connection of multi-layer materials, different plate thicknesses, and different materials can be achieved.

|

Product Type |

Metal Stamping Rivets/Aluminum Fastener Rivets/SS304 Rivets |

|

Material |

Sus, Iron (SPCC, SECC, SPTE), Aluminum Alloy, Copper, Brass, Bronze |

|

Heat Treatment |

Tempering, Quenching, Spheroidizing, Stress Relief. |

|

Application Scenarios |

Mechanical and Electrical Equipment, Furniture, Plastics, etc. |

|

Size Range |

M3-M8*5-120mmL |

|

Certification |

ROHS, SGS, etc. |

Factors to consider when selecting rivets

1. Material of the connected parts - metal or non-metal, hardness and brittleness of the material, etc.;

2. Plate thickness - the selected rivet ensures that the plate thickness is within its clamping range;

3. Connection strength, determine the tensile force and shear force required for the connection point of the rivet;

4. Hole size - the manufacturer specifies the matching hole size for the rivet nut, and you can refer to the manufacturer's design information;

5. Consider the coating thickness of the plate to avoid the hole becoming smaller after coating and not suitable for installation;

6. Material corrosion resistance - the material type and coating of the rivet should be based on the required corrosion resistance. Try to choose rivets of the same material as the connecting part. Different materials may cause galvanic corrosion;

7. Special requirements, such as flat head, countersunk head, double drum type, or lantern type;

8. Watertight and airtight requirements - watertight and airtight requirements of the riveted parts.

Why choose HY

1.HY is a professional production supplier, our main products are fasteners: bolts, screws, rods, nuts, washers, anchors and rivets. At the same time, our company also produces stamping parts and machined parts.

2.Mature quality inspection department, HY's quality inspection department will check each process to ensure the quality of each product. In the production of products, we will go to the factory in person to check the quality of products.

3.Professional export supplier, HY has a mature import and export system, complete qualification certification, and no obstacles in import and export collection and payment.