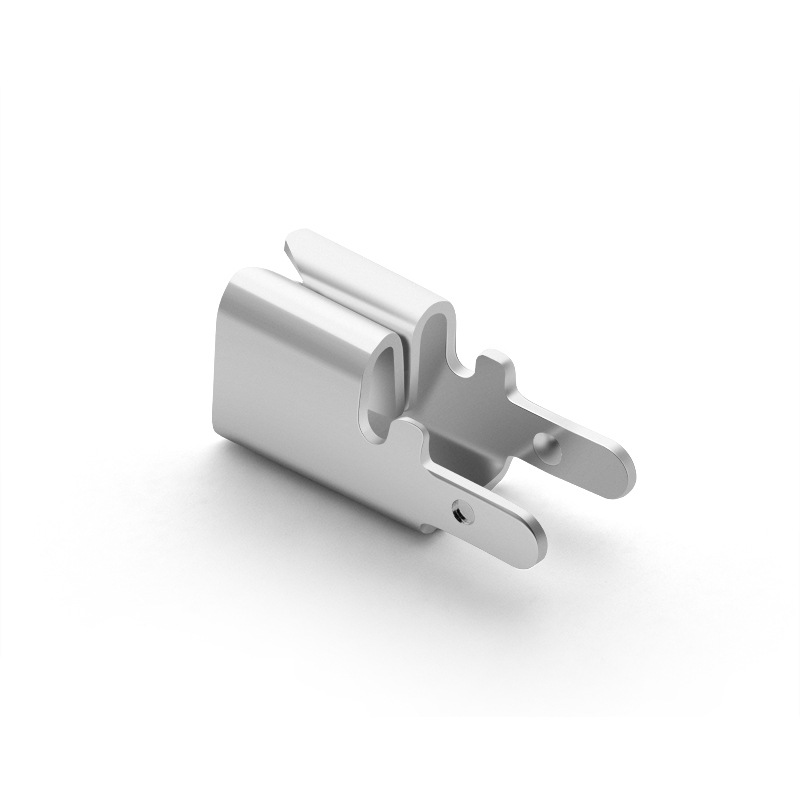

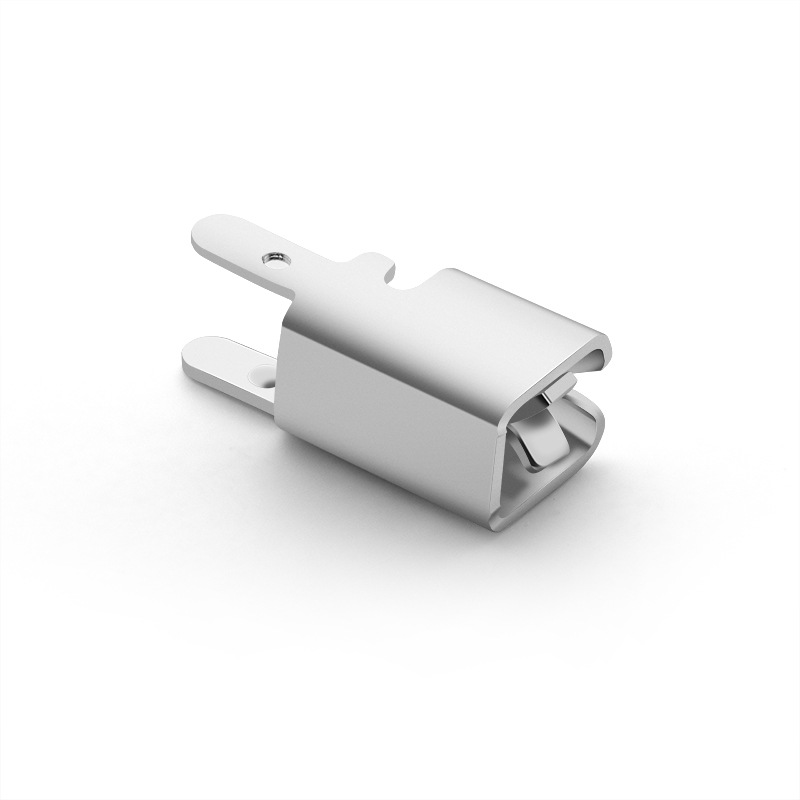

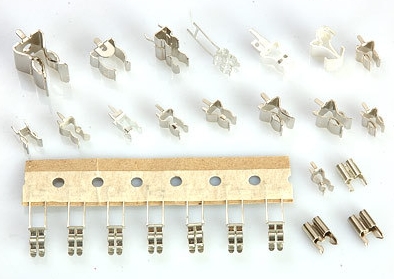

Metal Stamping Fuse Clips

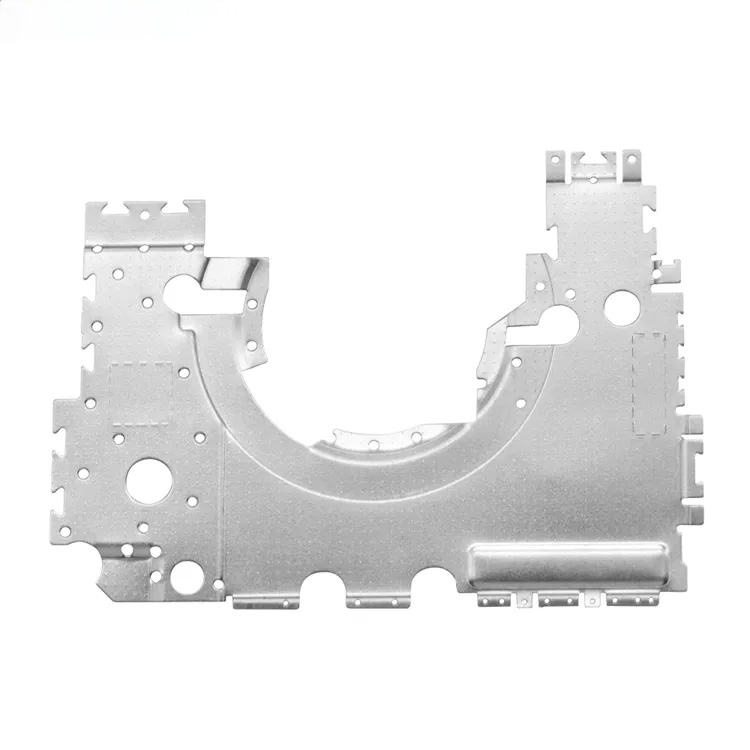

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirements

Send Inquiry

Metal Stamping Fuse Clips is a common electrical connector, mainly used to fix and support fuses, and plays an overcurrent protection role in the circuit. It is also called a fuse holder or fuse holder.

When the current exceeds the preset value, the fuse will disconnect and disconnect the circuit, preventing the equipment or system from further current damage and minimizing the loss. This is also the most common circuit protection measure now.

Working principle

Metal Stamping Fuse Clips mainly rely on the thermal effect of the fuse to work. The fuse is generally composed of a metal touch piece and a fuse. When the current flowing through the circuit exceeds the rated current of the fuse, it will trigger the fuse. The fuse will melt and cut off the circuit due to excessive heat, interrupting the current conduction.

The method of use is also very simple. Just install the Stamped Fuse Clips in the circuit and make sure that the pins and the pads on the circuit board are connected correctly.

Under normal conditions, the circuit and the current will flow from the pads on the circuit board to the pins of the Metal Fuse Clips when working, and then the current will flow through the metal touch piece to the working part of the load, such as light bulbs, motors, etc.

The fuses in Electrical Fuse Holders will only take effect when the circuit is overloaded. There is no difference in operation between normal and ordinary circuits. Once the current exceeds the safety threshold, the fuse will not be able to withstand it and will blow, protecting the system circuit safety.

Structural features

Metal Stamping Fuse Clips have become an important component in the circuit. Fuse Clips are used to connect the connection structure between the fuse and the circuit to ensure smooth current transmission. The outside is composed of an insulating base.

In operation, first of all, it is necessary to keep the base firmly fixed in the circuit board, align the pads of the Metal Fuse Clips and the circuit board correctly, use the correct welding method and tools to ensure the welding quality and prevent poor welding, and finally select the fuse with the appropriate circuit actual situation and current specification to ensure that the protection work is effective.

In addition, safety is no small matter. It is necessary to regularly check the status of the fuse and the connection of the Fuse Clips. Once an abnormality such as a blown fuse or other circuit abnormality is found, the fuse must be replaced or the circuit must be checked to ensure safe operation.

Selection parameters

The selection reference of Metal Stamping Fuse Clips generally has the following indicators: 1. Fuse type. Different types have different sizes and installation requirements. The selection of Stamped Fuse Clips should also be confirmed according to the fuse type.

2. Current carrying capacity. Fuses need to be able to withstand normal working currents to work properly. The same is true for Stamped Fuse Clips. Appropriate fuse specifications need to be selected to ensure that they will not blow under normal working conditions, and to prevent damage to the Electrical Fuse Holders when the circuit is overloaded.

3. Voltage level. The voltage level of Stamped Fuse Clips matches the working voltage in the circuit. The reason is the same. Too low will cause line damage, and too high will cause insufficient protection sensitivity and failure. There are professional High Voltage Fuse Clips available for selection and use in high-voltage environments.

4. Ambient temperature. The working temperature of Stamped Fuse Clips is also an important factor. Mechanical strength may be affected at high temperatures.

5. Installation method and size. This needs to be considered according to actual conditions. For example, for parts such as automotive circuit boards where the design space is relatively tight, whether there is enough space reserved to fix the Automotive Fuse Clips on the circuit board, whether there is reserved space for maintenance and replacement, etc.

6. Certification standards, such as CE certification, etc. Fuse Clips that meet the requirements of relevant standards with quality certification are more secure and meet regulatory requirements.

Why choose HY

1.HY can select the fuse clip with the appropriate rating according to your circuit operating voltage, current and expected maximum fault current to ensure that it can withstand the load and work correctly under overcurrent conditions.

2.HY supports OEM/ODM customization, taking into account factors such as temperature, humidity, vibration, including extreme environmental considerations, to support customers' special needs.

3.HY's fuse clips meet international safety standards and have relevant certifications, including electrical safety, fire protection, etc.

4.24-hour online service, which can respond quickly according to customer needs. HY quality commitment strictly controls and supervises the manufacturing process in accordance with ISO9001 standards, and implements an inspection system of self-inspection, mutual inspection and random inspection. Products are produced and inspected in strict accordance with the latest technical rules and standards at home and abroad. Friends from all over the world are welcome to visit our company.