China Pcb Mount Fuse Clips Manufacturers, Suppliers, Factory

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of "quality first, consumer supreme" for Pcb Mount Fuse Clips,Metal Fuse Clips,Stamped Fuse Clips,Electrical Fuse Holders,Fuse Clips, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

Pcb Mount Fuse Clips, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Hot Products

metal stamping small parts

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional stamping parts manufacturer. The metal stamping small parts produced by HY are widely used and suitable for stamping, shearing, forming, stretching, bending and other multi-purpose processing of metal sheets in large quantities.

Product name: metal stamping small parts

Customization: Customization is supported

Material support: stainless steel, aluminum, copper, titanium alloy, etc.

Drawing format: Stp, Step, Igs, Xt, AutoCAD (DXF, DWG), PDF or samplemotor mount

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a leading manufacturing and processing plant with 17 years of processing experience and a mature import and export qualification certification system. We are committed to providing high-standard and high-performance high-quality motor mount auto parts, making us competitive in the global market.

Product type: motor mount

Quality: 100% professional quality inspection

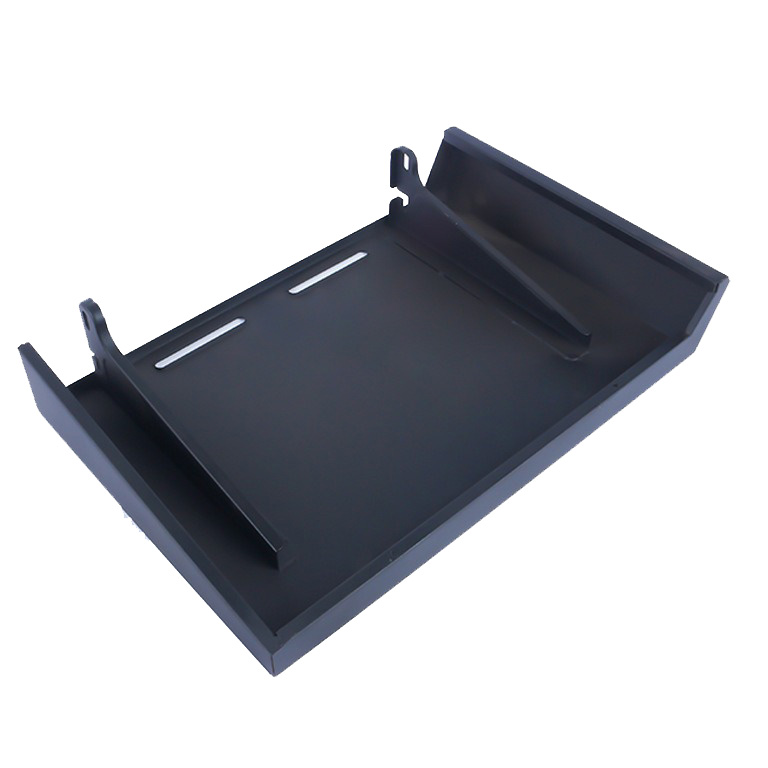

Customization service: support OEM/ODM customizationMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

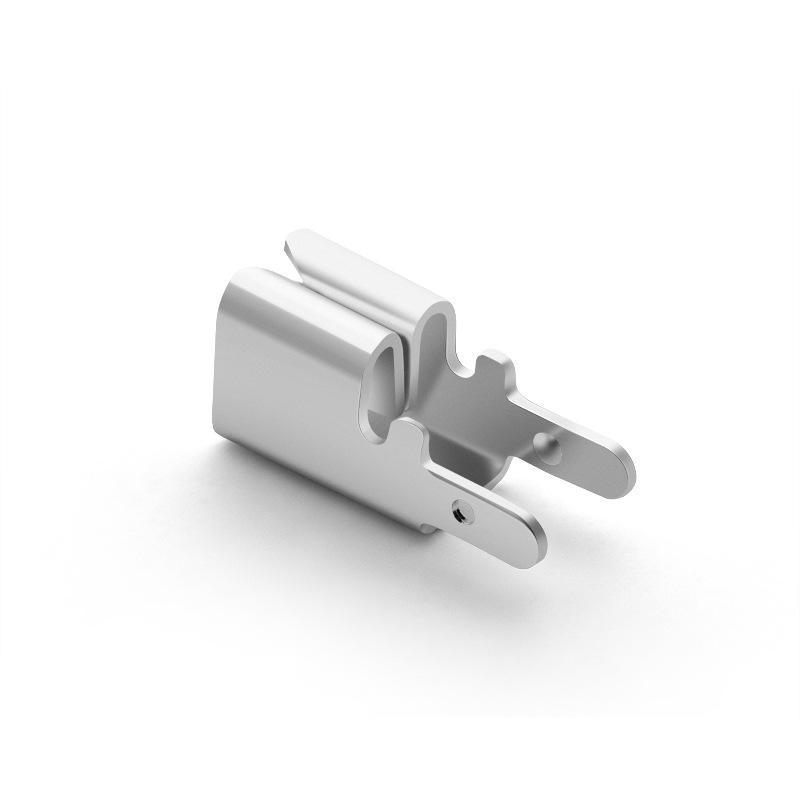

Application areas: medical equipment automation equipmentMetal Stamping Fuse Clips

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirementsEngine Turbocharger

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysDie Casting Windshield Wiper

HY is a Die Casting Windshield Wiper factory that provides aluminum die-cast windshield wipers. Commonly used materials for die-cast wiper rods: a380, adc12, alsi9cu3, zl104; surface smoothness of rough parts: ra1.6~ra3.2;