stainless steel screws

Xiamen Jiangjun Intelligent Technology Co., Ltd. specializes in the production of hardware accessories. It is a high-quality enterprise with "professionalism, innovation and service" as its core, and has therefore won the recognition and trust of customers. HY is committed to the research and development, production and sales of stainless steel screws fasteners, including 13 invention patents, 15 utility model patents and 1 design patent, demonstrating our technical expertise and innovation capabilities.

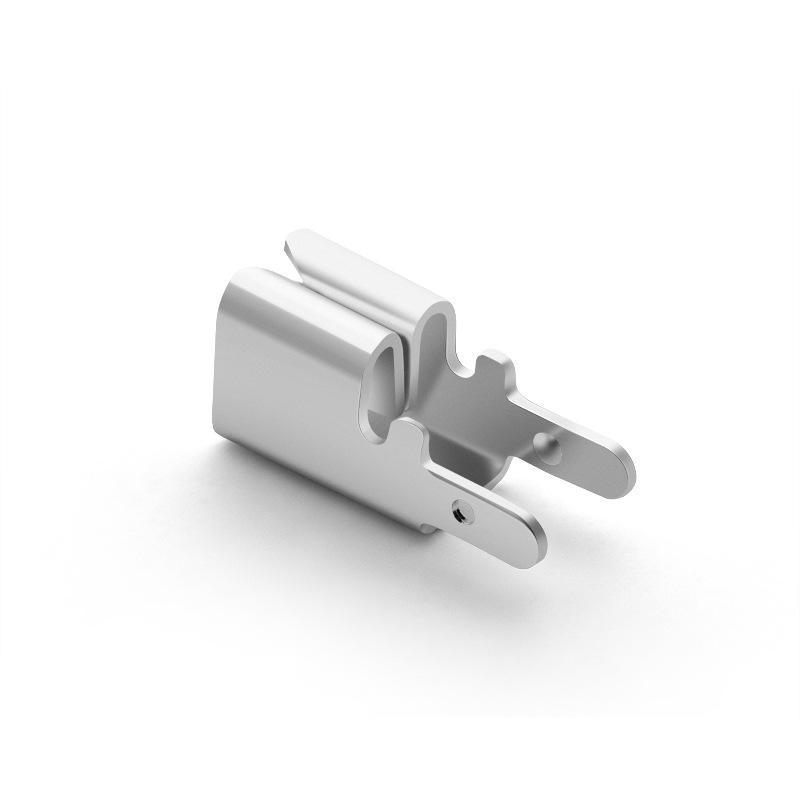

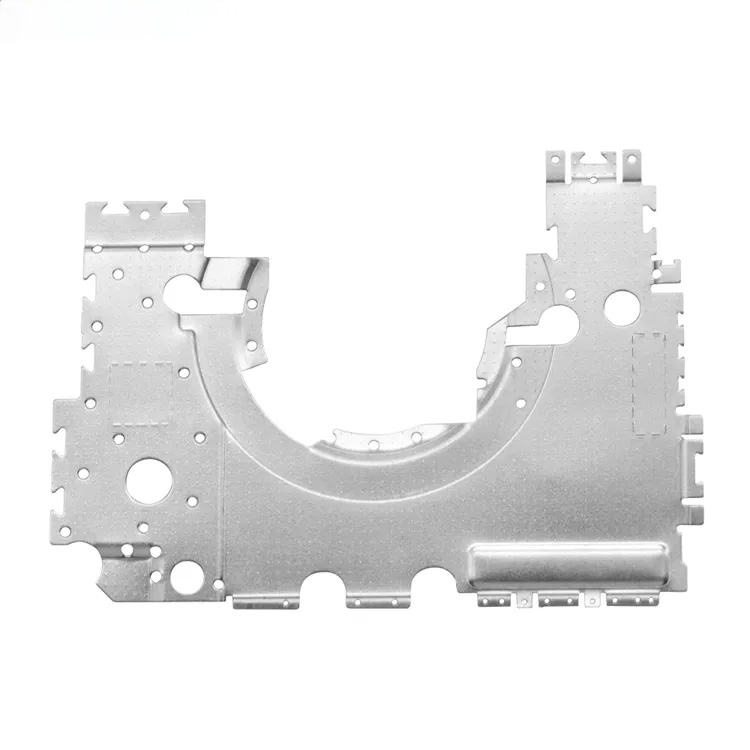

Hardware accessories: screw

Material: stainless steel, steel, brass, titanium, carbon steel, nickel, alloy

Surface treatment: black, galvanized

Quality: 100% full inspection, test and certification can be carried out according to customer special requirements

Send Inquiry

As the most common fastening part in daily life, stainless steel screws plays a vital role in everything from aerospace to daily necessities. Without the connection and fixation of countless screws, machines and equipment cannot form a solid whole and cannot operate.

Product Introduction

High-quality materials: Our screws are made of high-grade stainless steel, ensuring durability and corrosion resistance, suitable for a variety of industrial applications.

Customizable options: We provide customization according to customer requirements, including different surface treatments (black, zinc, ordinary, etc.), grades (4.8, 8.8, 10.9, etc.) and packaging options to meet specific needs.

Multiple head shapes: Our screws have a variety of head shapes, including pan head screws, truss screws, flat head screws, oval head screws, round screws, hexagonal screws, cheese head screws and binding head screws to meet different application needs.

Accurate measurement: Our screws use inch and metric measurement systems to ensure accurate installation on various machinery and equipment.

Fast delivery: We provide a standard delivery time of 30-40 days to ensure timely completion of projects according to user requirements and meet customer deadlines.

Compliant with international standards: Conforms to DIN933, DIN931 and DIN standards, ensuring compatibility with global applications, including automotive industry requirements.

|

Product Name |

Screws |

|

Size |

M1-M36, or non-standard according to requirements and design |

|

Grade |

4.8,8.8,10.9,12.9, etc. |

|

Standard |

GB, DIN, ISO, ANSI/ASTM, BS, BSW, JIS, etc. |

|

Customization |

OEM according to drawings or samples |

Screw processing technology

HY uses three-die three-punch processing technology to ensure the quality of parts.

Cutting: The wire stuck in the shear die is cut into the required blank through the unidirectional movement of the movable scissors.

One punch: The back punch presses against the blank punch to extrude the blank, and the blank is initially formed, and then the back punch pushes the blank out.

Two punches: The blank enters the second punch die, the second punch extrude, the blank is oblate, and then the back punch pushes the blank out.

Three punches: The blank enters the third punch die, and the blank is sheared by the hexagonal three-punch die core. The hexagonal head of the blank is initially formed. After that, the back punch pushes the blank into the third punch die, and the cut material is cut from the hexagonal head, and the hexagonal head is formed.

Why choose HY

Quality inspection: 100% inspection during the production process. Our products are certified by ISO9001 and TS16949 international quality standards.

Material customization: carbon steel, alloy steel, stainless steel, brass, copper or according to your requirements. Fast delivery: Standard parts: 7-15 days, non-standard parts: 15-25 days. We will deliver as soon as possible while ensuring quality.

We warmly welcome all customers to visit our factory. If you need an invitation letter from us, please contact us in advance.