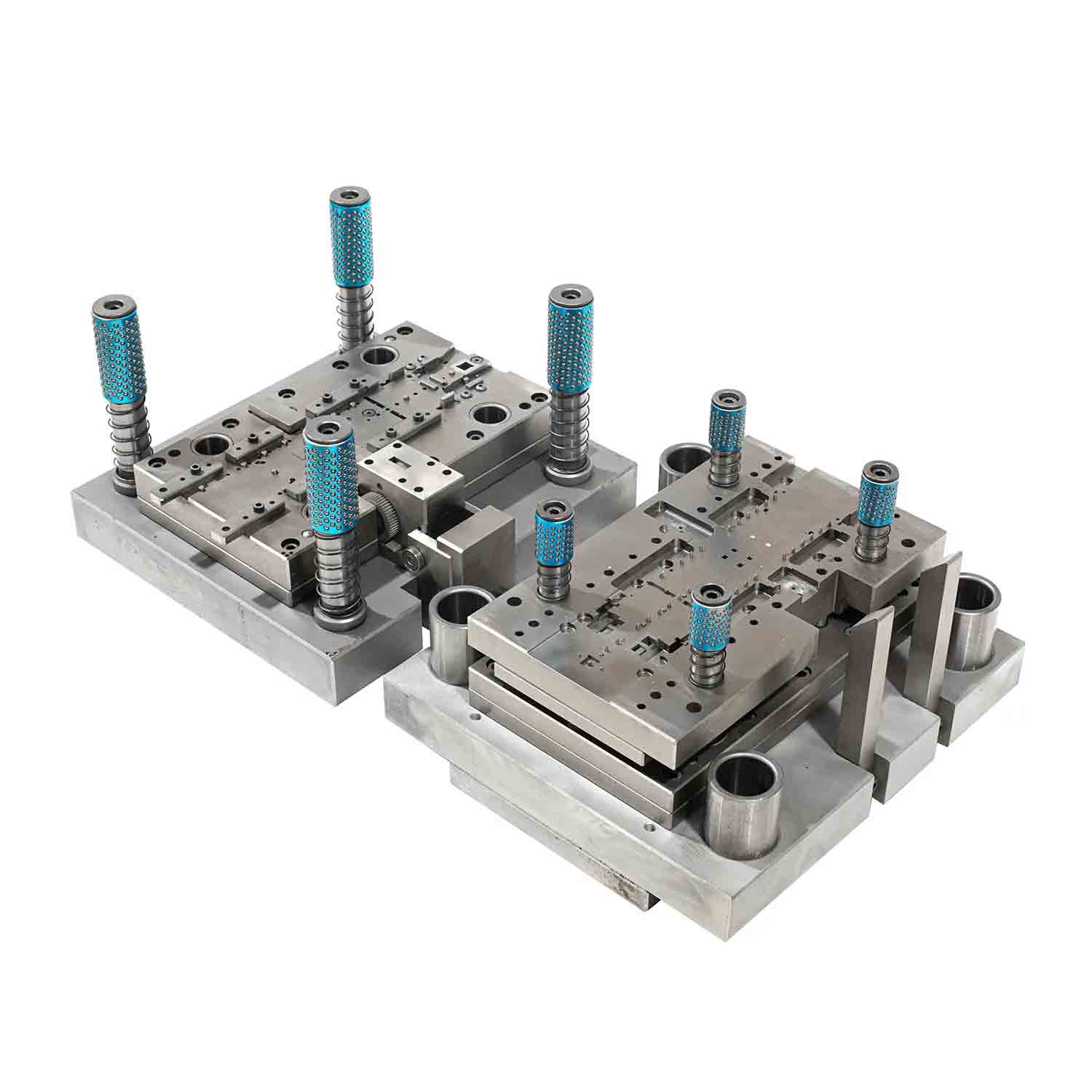

Custom Metal Stamping Dies

Xiamen Jiangjun Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.

Send Inquiry

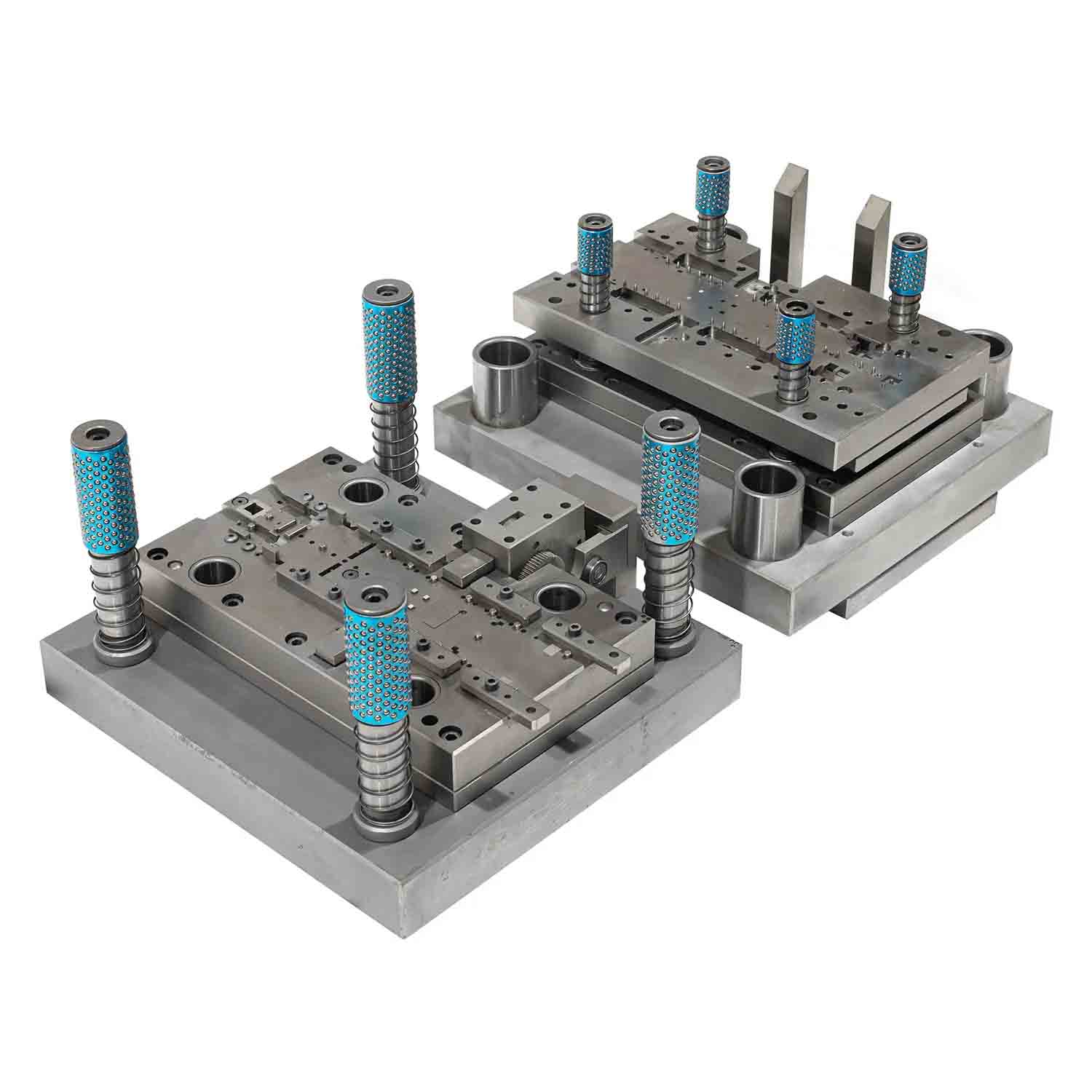

Custom Metal Stamping Dies production is a common industrial processing method that shapes materials in a certain way. It is a very common process in the production of batch products.

The application scenarios of mold processing are very wide, from automotive parts, aerospace, and hardware accessories, so molds also have the honor of "the mother of industry".

Forming characteristics of Progressive Stamping

Put metal or non-metallic materials in the Custom Metal Stamping Dies, and apply pressure through the press to deform the materials to get the parts we want. This is the stamping process. Stamping has a wide range of applications. It can process metal sheets, bars, and non-metallic materials. Stamping processing is mainly a processing process performed at room temperature.

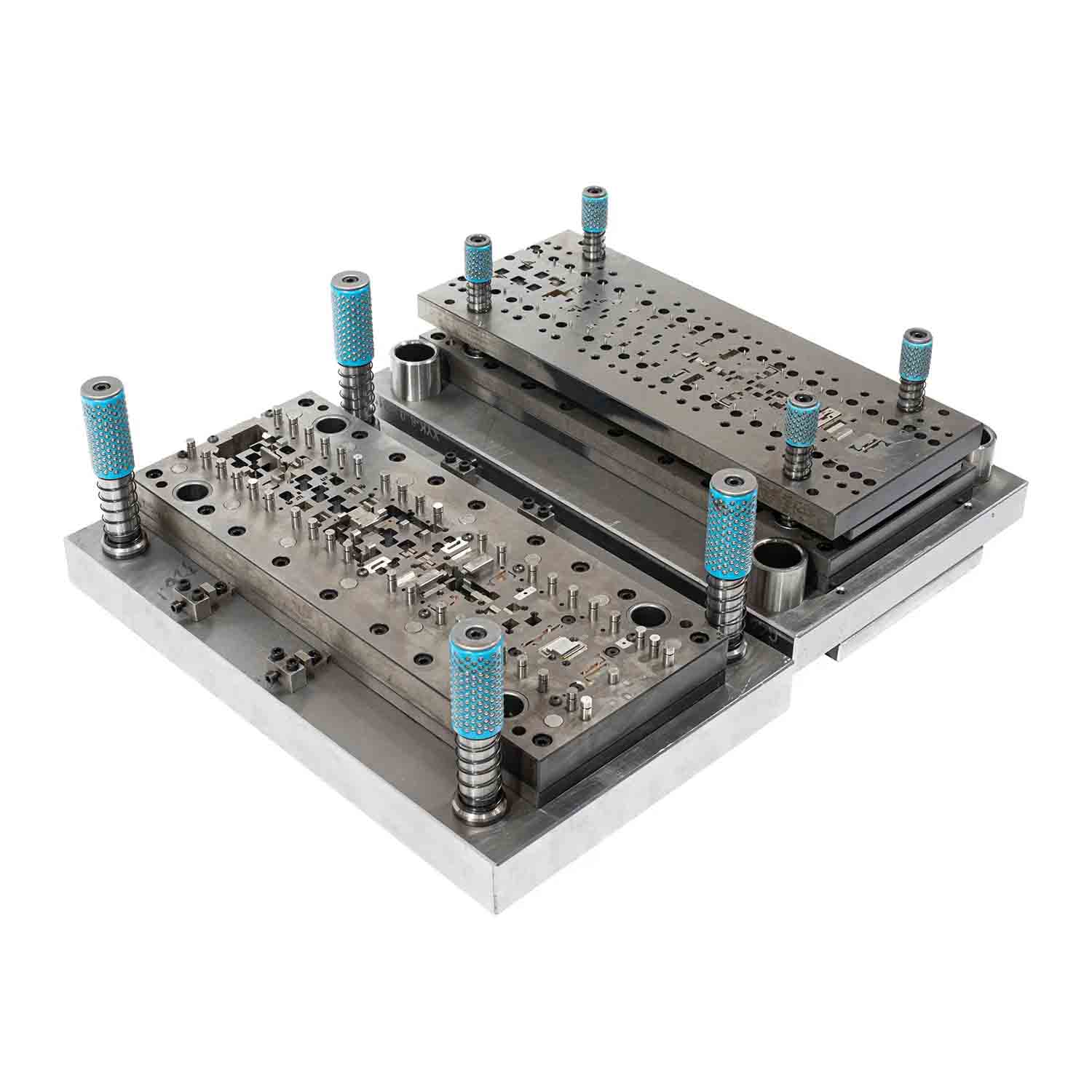

In addition to requiring high processing accuracy, Metal Stamping Dies manufacturing also requires good processing surface quality. The production and manufacturing tolerance of the working part of the normal mold needs to be controlled within ±0.01mm, and some parts with high precision requirements even need to be controlled at the micron level. At the same time, the surface roughness of the working part must also be less than 0.4um. The accuracy of the mold determines the accuracy of the product, and the roughness of the mold determines the roughness of the product.

The working part of Metal Stamping Dies is generally a complex curved surface composed of two or three dimensions, and the hardness of the material is required to be high. Normally, it is made of materials such as quenched tool steel to meet the high-intensity working requirements of repeated stamping processing of the die.

The various process performance requirements of stamping are not absolute, especially in the current rapid development of stamping technology. We need to combine the actual production needs and possibilities, select a reasonable processing method, and correctly formulate the stamping process and select the die structure. It not only meets the technical requirements, but also meets the conditions of the stamping process.

Determination of stamping process plan and Progressive Stamping structure type

The determination of the process plan is an important link after the process analysis of stamping parts, including the process analysis based on the shape characteristics, dimensional accuracy and surface quality requirements of the workpiece. First, all the basic processes that will be used should be confirmed and listed, such as blanking, punching, bending, drawing, flanging and bulging.

According to the process calculation, determine the number of processes, such as the number of drawing times for stretched parts, and the number of processing times for bent parts according to the requirements of shape and dimensional accuracy.

According to the deformation characteristics of the processing, the requirements of dimensional accuracy and the convenience of operation, the order of the processes is determined. For example, if a product requires two processing methods, punching and bending, should it be punched first and then bent, or bent first and then punched?

According to various factors such as production batch, size, accuracy requirements, Progressive Die Stamping manufacturing level, equipment capacity, such as compound stamping process, continuous stamping process, etc., generally speaking, large batches, low accuracy requirements, thick materials, and large-sized products are suitable for single-process production; while high-precision products are suitable for compound die stamping.

The design of Custom Metal Stamping Dies is a systematic and comprehensive process involving material deformation, mechanical calculation and precision machining. For example, the punching die is a die used for cutting, blanking or punching. Most of them are used for gaskets, hardware cutting and other aspects. The cutting surface of the die needs to be repeatedly punched, so it is necessary to consider heat treatment of the cutting edge, such as processing to HRC58-62 degrees, or titanium plating. This can extend the service life of the die and reduce the impact of excessive burrs on the cutting of accessories due to wear and tear of the die.

Why choose HY

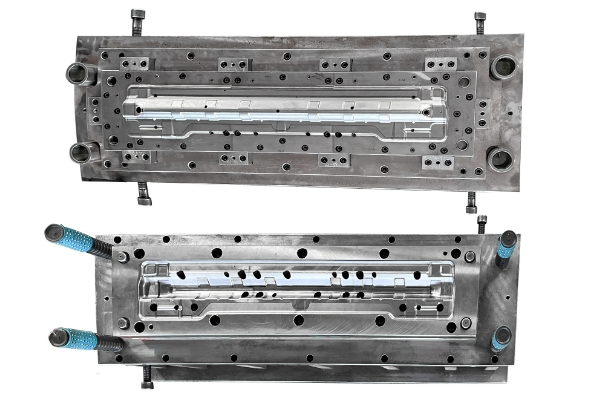

High-precision Custom Metal Stamping Dies and die-casting dies are the core of Xiamen Jiangjun Intelligent Technology Co., Ltd. We provide manufacturing in the fields of automobiles, semiconductors, consumer electronics, commercial machinery and equipment, medical life sciences, etc. Choosing HY means choosing to be a partner with experts throughout the production cycle. We are committed to turning customers' products from concept to reality.

HY supports 3D models in other formats such as stp and step, as well as quotations for 2D drawings with tolerances, materials, finishes, test requirements and regulations.

Our largest stamping die can currently be 2500mm long and 1000mm wide, and we have 400T testing equipment.