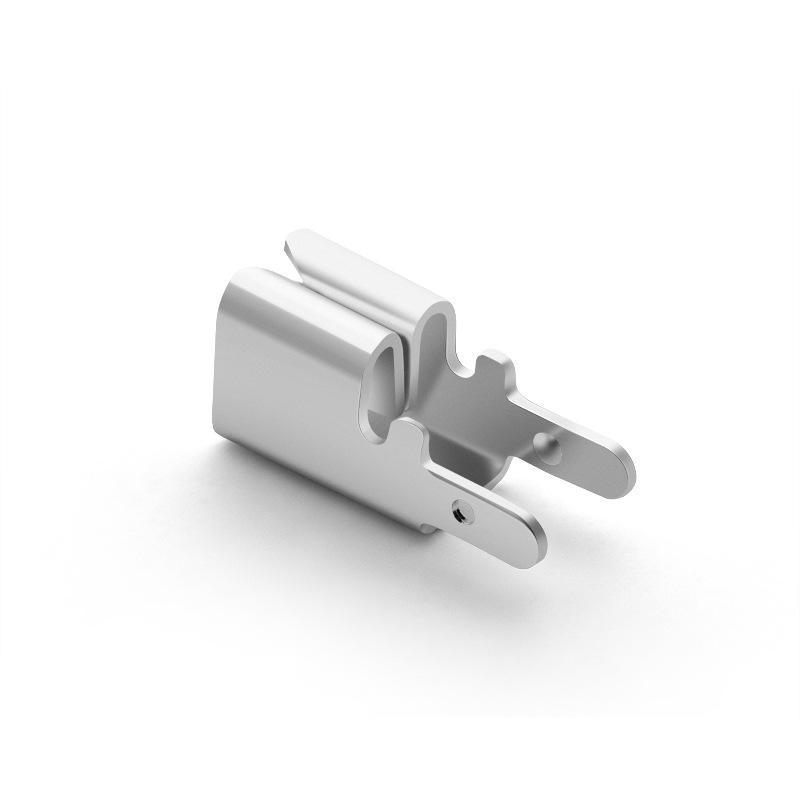

screw washer

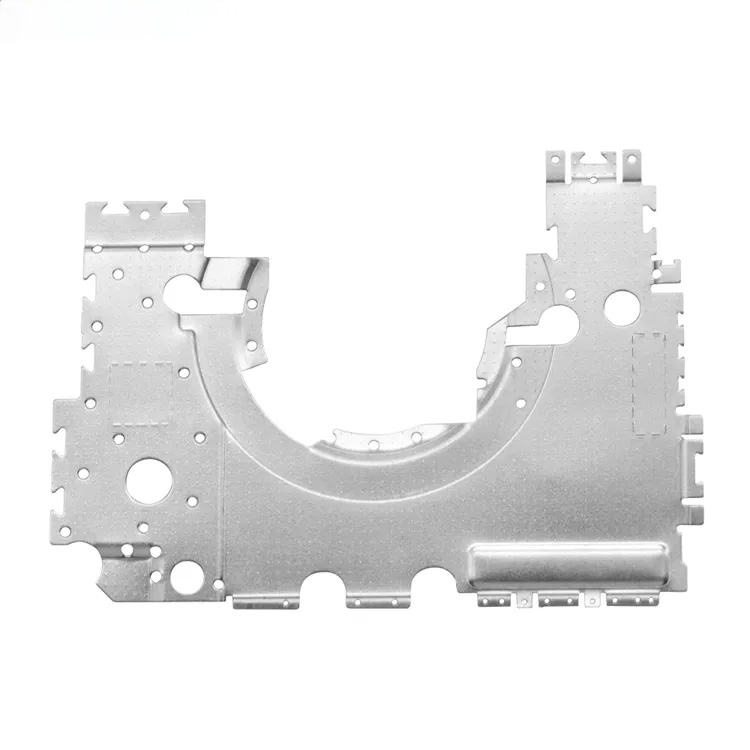

Xiamen Jiangjun Intelligent Technology Co., Ltd., has three steel hardware manufacturing plants and a 3,000 square meter logistics warehouse. HY is specialized in building stampings, fasteners and automotive parts. We produce and supply a whole range of screws,screw washer, nails, bolts, nuts, threaded rods, anchors, couplers, stampings, connectors, plastic parts, pipes, chains, etc. Our products meet international quality standards such as DIN, BS, ANSI, JIS, etc.

Material: Carbon Steel

Surface Treatment: Galvanized

Size: Metric, Imperial

Send Inquiry

Bolt connection is a common connection and fastening method, and washers are small components commonly used in bolt connection, and are one of the most important auxiliary fasteners.

Washers are generally flat metal rings, and their main function is to buffer, isolate, and seal between two fasteners to ensure the stability and reliability of fasteners.

Flat washers and spring washers are commonly used types of washers in mechanical connections, each of which plays an indispensable role and has different scopes of application.

|

Grade |

A2-70 / 4.8 |

|

Applications |

Machinery and equipment, construction, heavy industry, mining, retail industry, general industrial use, automotive industry, household use |

|

Model |

screw washer |

|

Customization service |

Customization is supported |

Common occasions for washers

1. In occasions where bolts need to be disassembled frequently.

In order to protect the surface of the connected parts from being scratched, it is generally necessary to place flat washers at the nut or bolt head position, so as to prevent the surface of the connected parts from being scratched, especially for surfaces processed by precision machining.

2. In some connections where the friction coefficient requires a relatively precise requirement, there is no separate test requirement for the friction coefficient.

For example, in wind power bolt connections, combined bolts, nuts, and washers are generally used for connection. In this case, the bolts, nuts and washers are all provided by the same manufacturer. The bolt manufacturer needs to process the nuts and washers accordingly to ensure that the friction coefficient between the nuts and washers remains consistent. In addition, the supplier will be required to test the torque coefficient to meet the technical requirements.

3. When the bolt strength is relatively high and the compressive stress of the connected parts is relatively low.

For example, the requirements for lightweight automobiles are getting higher and higher. In the body and even the chassis structure, a large number of lightweight connection technologies and structures are used to reduce the compressive stress of the pressure-bearing surface of the connected parts in the bolted joints to prevent crushing and permanent plastic deformation.

The role of washers

In bolted connections, the pressure transmission of the bolt head or nut pressure-bearing surface is gradually expanded in a trumpet shape. The larger the pressure-bearing surface, the smaller the compressive stress. Therefore, the use of flat washers can reduce the compressive stress of the contact surface of the connected parts and ensure the effectiveness of the bolted connection.

For connections that need to be sealed, the stress distribution diameter of the stress cone on the joint surface is increased. In this way, adding washers can ensure the sealing effect.

In some occasions, such as automobiles mostly use stamping parts and welded parts, the position of the holes between the two parts cannot be accurately matched. In order to ensure that the bolt holes between the two connecting parts can correspond one to one, we need to increase the diameter of the hole to compensate for the position deviation of the hole. When the bolt hole exceeds the standard requirements, the compressive stress exceeds the strength of the material. In this case, it is necessary to add a flat washer.

Sometimes, for the convenience of installation and adjustment, such as the connection between the control arm bracket and the control table, one of the bolt holes in the two bolt connections will be made into a long hole, so that the installation position of the workpiece can be adjusted within a certain range. When using a long hole, a thickened flat washer must be used, and sometimes even a special washer or multiple washers are used.

Why choose HY

1. Bolts, nuts, and washers are all produced independently to achieve effective batch control, while ensuring the precision matching of bolts, nuts, and washers, and improving the stability of the adaptability test of the connection pair.

2. HY uses shot blasting technology to replace the traditional pickling process. There is no pickling during material processing and surface treatment, avoiding the risk of product hydrogen embrittlement caused by pickling.

3. All hot-galvanized nuts produced by HY are tapped once after hot galvanizing, which effectively improves the thread strength of the nut and avoids the nut stripping caused by secondary back-threading.

4. All products are 100% quality inspected, and support third-party testing and factory inspection to ensure the authority, independence, fairness and standardization of data. New and old customers at home and abroad are welcome to contact us.