China screw washer Manufacturers, Suppliers, Factory

Our pursuit and company purpose is always to "Always satisfy our consumer requirements". We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for screw washer,nuts bolts and washers,nut bolt washer,screws and washers,washers and bolts, We feel that our warm and experienced company will bring you pleasant surprises as perfectly as fortune.

screw washer, We adopted technique and quality system management, based on ""customer orientated, reputation first, mutual benefit, develop with joint efforts"", welcome friends to communicate and cooperate from all over the world.

Hot Products

auto battery tray

Xiamen Jiangjun Intelligent Technology Co., Ltd. has been committed to the development of low-voltage components, lighting components, automation components, medical equipment components, communication components and precision equipment components. We have been committed to stamping and assembly production for many years. We have accumulated rich experience in the field of auto battery tray. Our products are widely used in various high-power battery packs, electric vehicle battery packs, solar street lights, military battery packs, etc., which can meet the needs of most customers. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various application scenarios according to customer needs.

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

Application scenarios: automobiles, electric vehicles, ships, etc.motorcycle cylinder head

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer and exporter of motorcycle cylinder head. HY has a complete range of products, mainly motorcycle engine systems, including cylinder blocks, pistons, piston rings and cylinder heads, cams, rocker arms, crankshafts, connecting rods, main and secondary shafts, etc.

Material: Aluminum Alloy

Product Name: Motorcycle Cylinder Head

Proofing Service: Proofing Support

Accessories: Piston Kit, Gasket

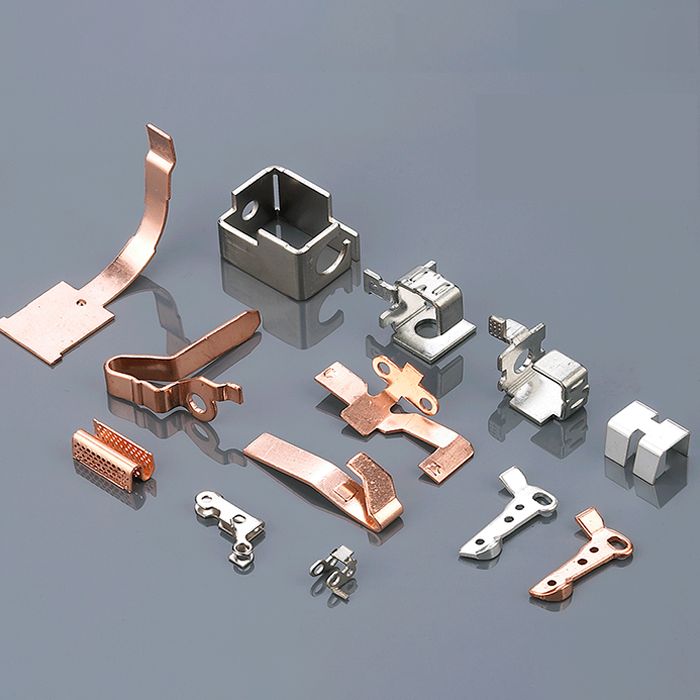

Quality Inspection: 100% Full InspectionMetal Stamping Electronic Wire Assemblies

HY is a Metal Stamping Electronic Wire Assemblies factory that custom-processes metal stamped electronic wire assemblies.The industries served by HY include home appliances, electrical equipment, electronics, and lighting. Nearly 20 years of experience in Precision Metal Stamping.self tapping screws

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of fasteners and curtain wall accessories. It produces and sells stainless steel self tapping screws, machine screws, nuts, bolts, rivets, washers, anchors, stainless steel undercut anchors, aluminum extrusions, expansion screws and other standard or non-standard fasteners and curtain wall accessories. HY has a complete quality management system, advanced quality testing equipment and a professional quality management team. The product quality adopts batch traceability management.

Material: brass, stainless steel, steel, aluminum, nickel, bronze

Surface treatment: zinc, blackening, galvanizing, zinc-aluminum coating, chrome plating, Ruspert

Screw head type: pan, large round flat head, flat top, oval, round, hexagonal, hexagonal washer

Processing technology: stamping cold headingAluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 daysStamping Busbars

HY is a factory that produces progressive high-speed Stamping Busbars.Stamping Busbars is a key component of electric vehicles, and copper, brass and aluminum are the three most common busbar materials. Busbars are most commonly used in three-phase power distribution systems.