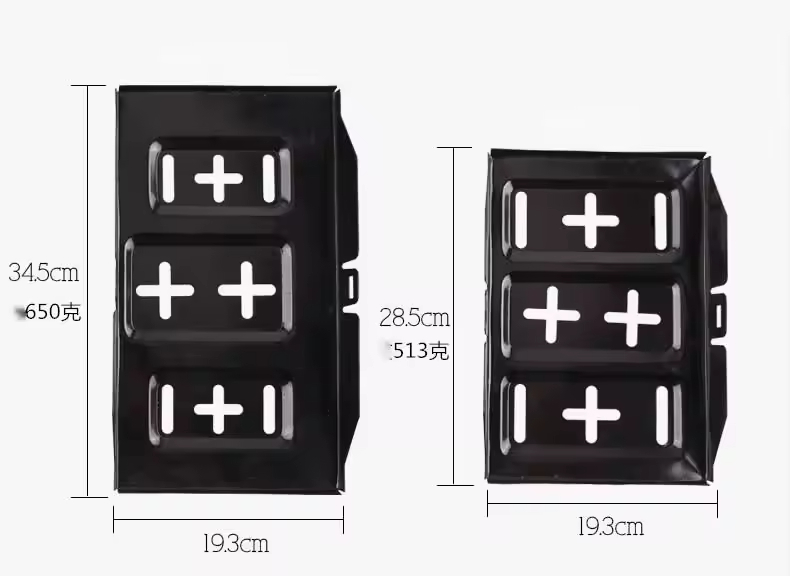

auto battery tray

Xiamen Jiangjun Intelligent Technology Co., Ltd. has been committed to the development of low-voltage components, lighting components, automation components, medical equipment components, communication components and precision equipment components. We have been committed to stamping and assembly production for many years. We have accumulated rich experience in the field of auto battery tray. Our products are widely used in various high-power battery packs, electric vehicle battery packs, solar street lights, military battery packs, etc., which can meet the needs of most customers. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various application scenarios according to customer needs.

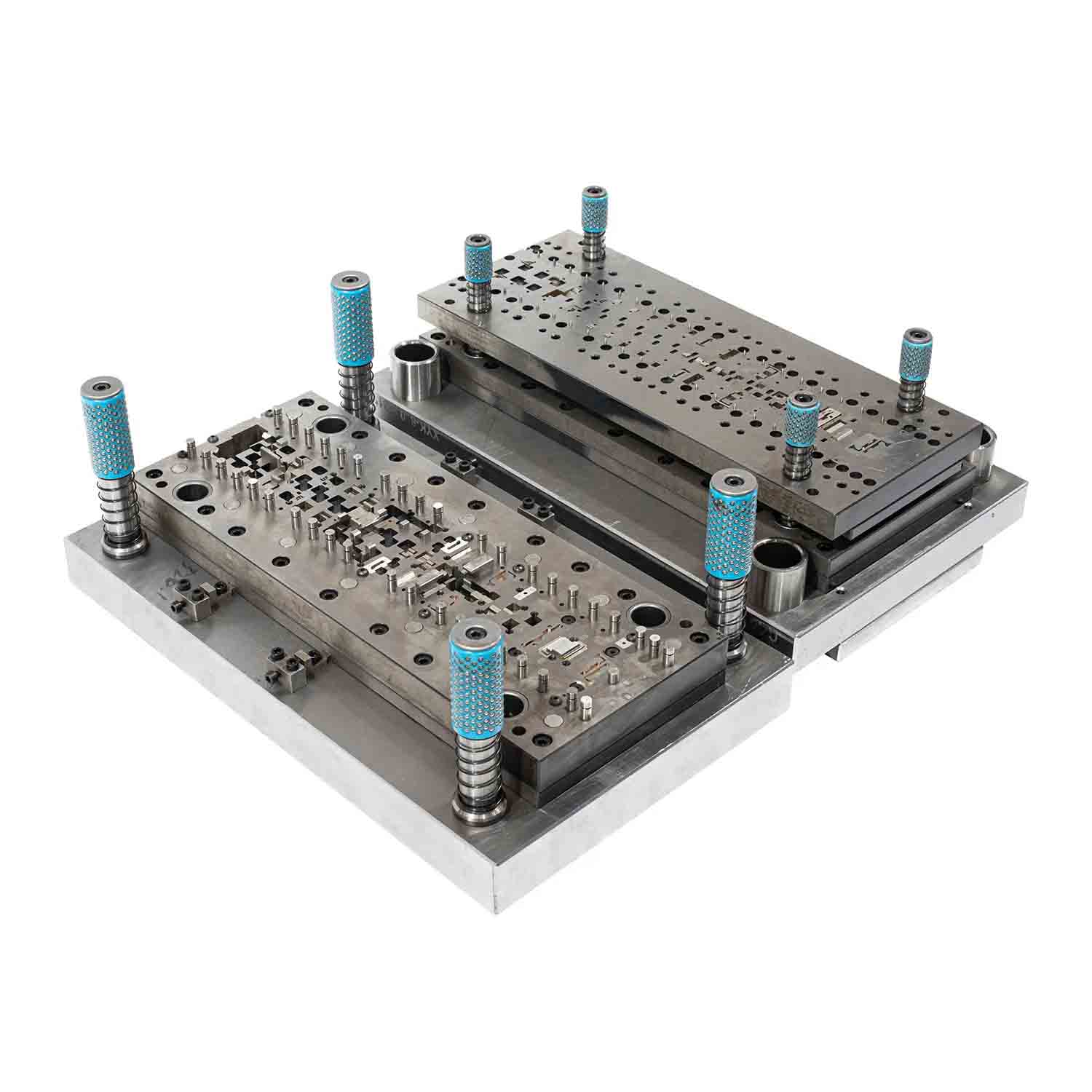

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

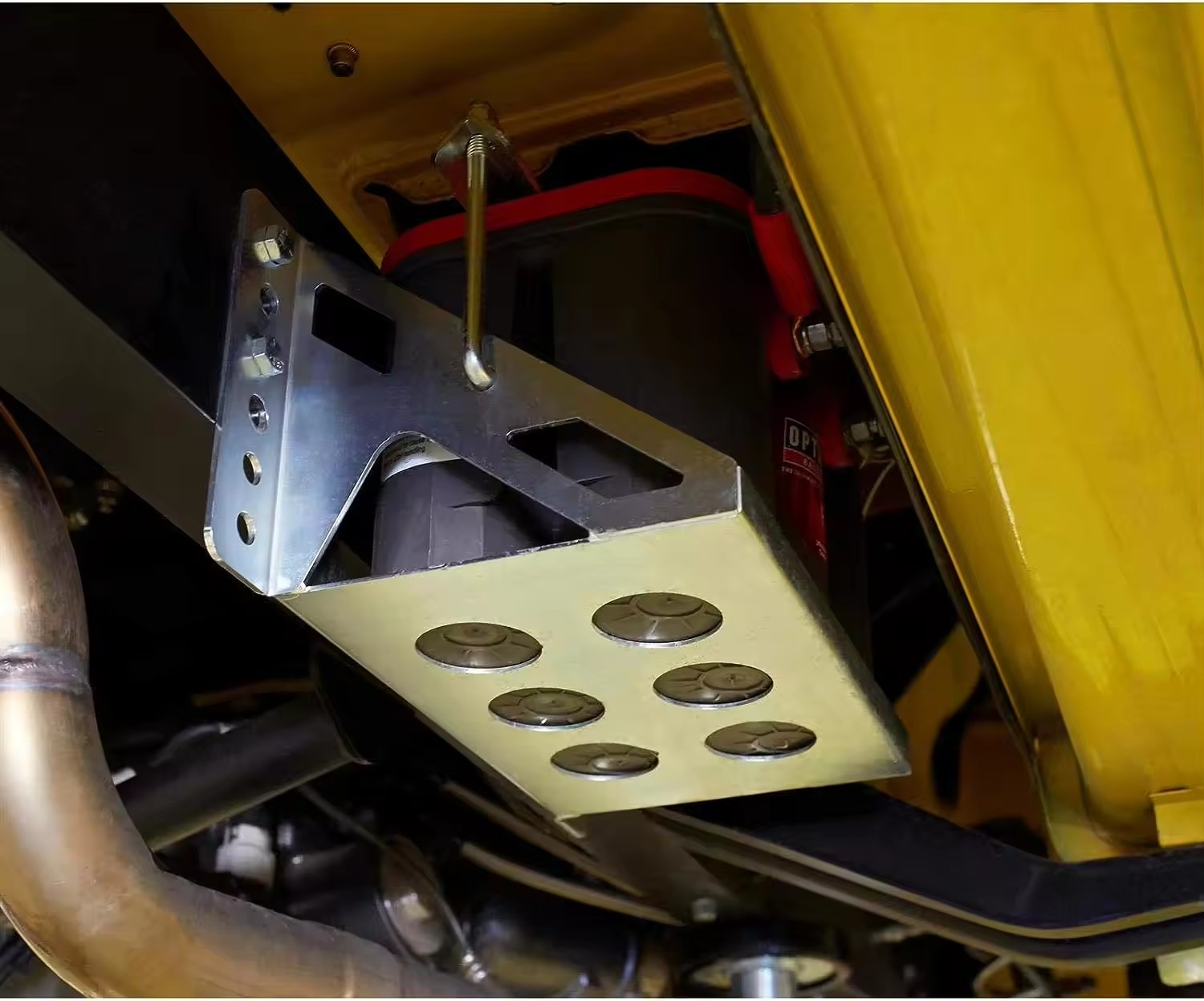

Application scenarios: automobiles, electric vehicles, ships, etc.

Send Inquiry

New energy vehicles use batteries as power to drive the vehicle, and auto battery tray plays a key role in protecting the normal and safe operation of the battery.

At present, there are three common auto battery trays, namely steel battery box, aluminum die-cast battery tray and aluminum extruded battery tray, and aluminum extruded battery tray has the largest market share due to its various advantages.

Processing technology of auto battery tray

Among the three auto battery trays mentioned above, the share of steel battery box has gradually shrunk with the continuous market competition. The density of aluminum battery tray is smaller and lighter, so it is more energy-saving. And because most batteries are at the bottom of the car body, they are subject to long-term corrosion and impact from moisture, soil and minerals, and the chemical properties of aluminum are more stable and corrosion-resistant.

In addition, aluminum has good ductility and better processing performance than steel, which makes the production cost and difficulty of aluminum much lower than that of steel.

Among them, aluminum extruded battery tray and aluminum die-cast battery tray have their own advantages and disadvantages, and have different positioning and choices for different application scenarios. The design of extruded aluminum battery tray is more flexible and easier to modify and improve the design plan. Therefore, aluminum extrusion has various specifications and is widely used, which is very common in various fields.

Structure of auto battery tray

The aluminum battery tray is made of extruded aluminum profiles as the basic material. The various components are combined into a whole by welding to form a complete frame structure.

Plates are used in some positions as sealing plugs for the profile cavity. Fasteners include hexagonal rivet nuts, pressure rivet studs, and screw sets of appropriate sizes selected according to needs.

The main components of lithium battery tray include bottom plate, left profile side beam, right profile side beam, front profile side beam, rear profile side beam, module mounting beam, etc. The four side beams use three different cross-section L-shaped profiles, which are more conducive to welding with the bottom plate.

The two module mounting beams are located on the welds of the bottom plate and the front and rear profile side beams, respectively, and serve as the support plane and connection point of the battery tray holder.

Multiple hexagonal rivet nuts are installed on the upper edge of the universal battery tray to connect the upper cover of the battery pack to form a closed space, thereby ensuring the normal operation of the battery module.

HY targets customer needs, confirms customer usage scenarios, continuously improves processes, and designs targeted and personalized structures to ensure that customer usage requirements are met.

Why choose HY

HY supports the production of auto battery trays of various specifications and styles, supports customization, and provides tailor-made technical services for various models of cars according to customer needs.

Professionals docking, fast delivery time from the first communication to the completion of the design, the shortest is only 20 days.

A team with more than 10 years of processing experience guarantees processing quality. The higher the welding accuracy, the better the battery sealing, which can greatly reduce air leakage, water leakage, etc., and improve the battery safety factor.

Mature logistics system and delivery system, providing full tracking services, product transportation pictures, packaging size and weight, transportation marks, etc., including customer required packing list and other requirements, logistics company and logistics tracking number.