China subframe car Manufacturers, Suppliers, Factory

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for subframe car,subframe,rear subframe,front subframe,sub frame, We welcome new and old consumers from all walks of everyday living to speak to us for upcoming business enterprise interactions and mutual accomplishment.

subframe car, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.

Hot Products

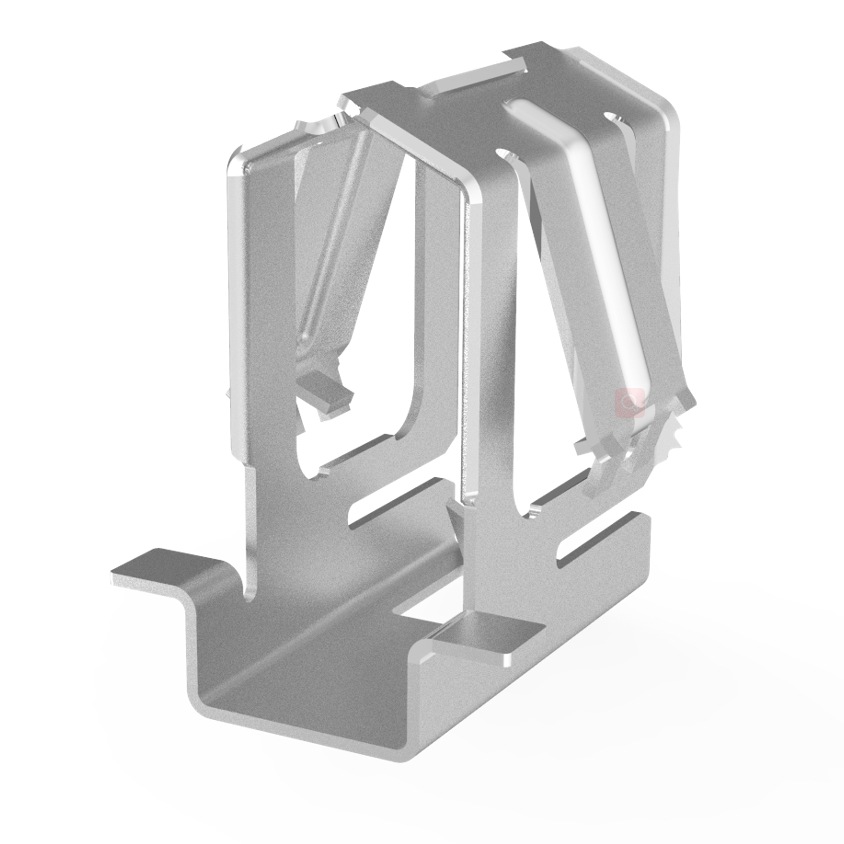

auto battery tray

Xiamen Jiangjun Intelligent Technology Co., Ltd. has been committed to the development of low-voltage components, lighting components, automation components, medical equipment components, communication components and precision equipment components. We have been committed to stamping and assembly production for many years. We have accumulated rich experience in the field of auto battery tray. Our products are widely used in various high-power battery packs, electric vehicle battery packs, solar street lights, military battery packs, etc., which can meet the needs of most customers. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various application scenarios according to customer needs.

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

Application scenarios: automobiles, electric vehicles, ships, etc.motorcycle cylinder head

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer and exporter of motorcycle cylinder head. HY has a complete range of products, mainly motorcycle engine systems, including cylinder blocks, pistons, piston rings and cylinder heads, cams, rocker arms, crankshafts, connecting rods, main and secondary shafts, etc.

Material: Aluminum Alloy

Product Name: Motorcycle Cylinder Head

Proofing Service: Proofing Support

Accessories: Piston Kit, Gasket

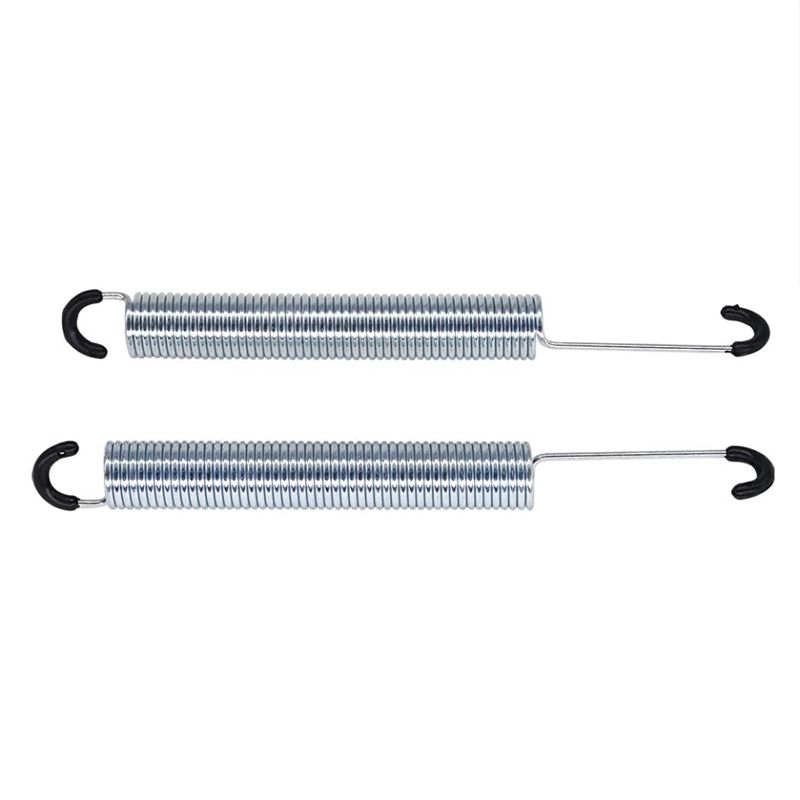

Quality Inspection: 100% Full InspectionStamping Wire Formed Fasteners

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.medical wheelchair

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in the production and supply of high-quality medical care products. HY has established a good reputation through high-quality and professional production, quality control and customer service. We provide a variety of hospital or home care products, including wheelchairs, trolleys, bathroom series, walkers, crutches and beds, etc.

Product type: medical wheelchair

Material: carbon steel, aluminum alloy, stainless steel, carbon fiber

Processing method: precision stamping

Load limit: 136KG

Recommended population: patients with impaired walking function, the elderly, patients in rehabilitation periodDie Casting Chassis

HY is committed to producing Die Casting Chassis to provide optimal strength and is a manufacturer and trader of stamping and die-cast products. enhance the power of the frame. The materials used are carefully and rigorously selected to extend the service life.Stainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray Painting