China knee crutch Manufacturers, Suppliers, Factory

We're going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for knee crutch,peg leg crutch,leg crutch,broken leg and crutches,hands free leg crutch, Welcome all nice buyers communicate details of products and ideas with us!!

knee crutch, Our goods are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have now got high praise by partner. We're looking forward to establishing business relationship with you.

Hot Products

metal junction box

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of cable connectors and waterproof metal junction box. HY integrates R&D, production and sales. It focuses on shaping the PULTE brand and provides excellent technical performance, efficient quality assurance, satisfactory sales services and reasonable prices. Its products are widely used in various fields such as junction boxes, distribution cabinets, communication equipment, instrumentation, medical equipment, machine tools and machinery.

Thickness: 0.7mm-1.6mm

Product type: stainless steel junction box, metal j box

Color: silver, natural color, according to customer needs

Material: MS, SS, GAL, SGCC, ALU, brass

Surface treatment: spray painting \ powder coating \ electroplating \ polishingAluminum Alloy Die Casting

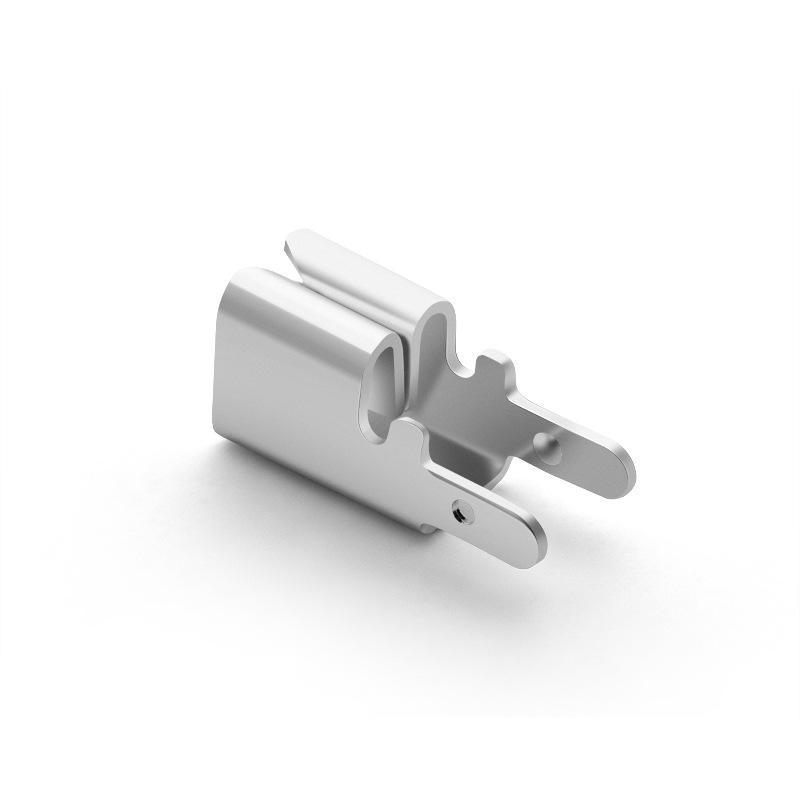

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 daysStamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing partsMetal Brand Seal

Customized Metal Brand Seal, mirror polished, solid brass HY designs a unique seal taste for you. The iconic "shiny" head is machined from a solid brass blank and coated with an ultra-fine ceramic layer.Car Differential

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of automotive parts for heavy and light vehicles at home and abroad. Including drive axles, suspension components, gearboxes, Car Differential and other products. HY In order to ensure product quality, we have imported advanced production equipment and testing equipment, including American HASS lathes, Japanese FANUC manipulators, three-dimensional coordinate measuring machines, etc. We welcome inquiries and feedback from customers at home and abroad.

Application range: automotive transmission, industrial machinery

Surface treatment: carbonization, sandblasting, can be customized according to customer needs

Processing technology: die castingEngine Turbocharger

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 days