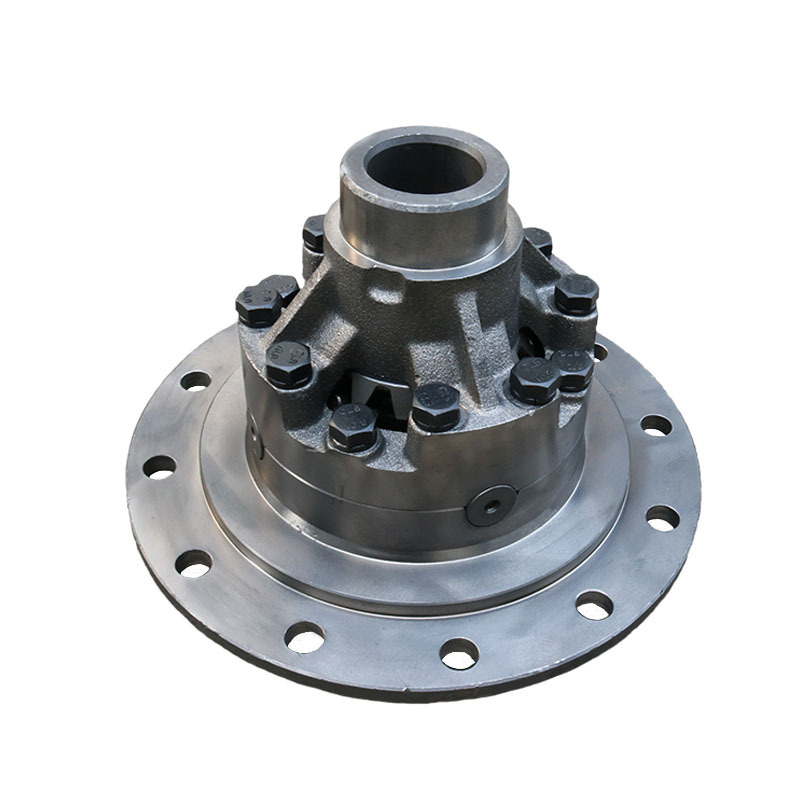

Car Differential

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of automotive parts for heavy and light vehicles at home and abroad. Including drive axles, suspension components, gearboxes, Car Differential and other products. HY In order to ensure product quality, we have imported advanced production equipment and testing equipment, including American HASS lathes, Japanese FANUC manipulators, three-dimensional coordinate measuring machines, etc. We welcome inquiries and feedback from customers at home and abroad.

Application range: automotive transmission, industrial machinery

Surface treatment: carbonization, sandblasting, can be customized according to customer needs

Processing technology: die casting

Send Inquiry

The main function of Car Differential is to ensure that the car body can still drive normally when the speeds of the wheels on both sides are inconsistent, and to reduce the load pressure on the wheels and the car drive shaft caused by the speed difference.

Perhaps most people would think that it is very counterintuitive for the wheels on both sides to have different speeds when the wheels of the car are always in a state of synchronous forward and synchronous stop, but in fact, the speed difference on both sides of the car body is very common. For example, when turning, the outer wheel has to travel a longer distance than the inner wheel in the same time. The function of Car Differential is to eliminate the extra load caused by this distance difference, reduce the discomfort of the posture and protect the transmission parts.

|

Product name |

Die cast automotive differential |

|

Color |

Silver, black, metallic, customizable |

|

Noise |

Low noise |

|

After-sales service |

Online support |

|

Gear accuracy grade |

Grade 7 |

Classification and processing of Die cast automotive differential

Car Differential is the core structural component of the automotive gearbox. Different models and different differential structures will lead to different final shapes and structures, but we can roughly divide the differential into two types: integral and split.

In terms of processing technology, the processing difficulty of integral differential is higher than that of split.

Current Car Differential processing can be divided into NC cutting and die casting forging. The advantages of the gears of die casting forging differentials meet the needs of various car, truck and other car manufacturers. They are tailor-made, with large output and lower cost than cutting processing. They meet the power of differentials and have sufficient strength and durability to meet the use requirements and safety performance.

NC cutting processing for differentials usually requires the modification of lathes for processing. The modification cost needs to be estimated according to the actual situation, but it will not be too low in any case.

Die casting forging differentials have processing advantages that other processing methods cannot match in mass production, and due to the size limitations of the drive housing and body design, the space that each component can occupy is limited. This means that when Car Differential is designing and producing, it is necessary to strike a balance between size and durability, which is a point that must be considered in all designs.

HY's Die cast automotive differential is die-casted with 20CrMnTi and other materials. After two heat treatments and two forgings, the gear tooth surface accuracy is improved, the contact area between the planetary gear tooth surface and the side gear tooth surface is increased, the contact pressure is more uniform, and the noise is reduced.

Multi-purpose furnace carburizing is adopted, the hardness of the carburized layer is uniform, the tooth surface deformation is reduced, and the service life of the gear is increased.

As a professional Die-cast auto parts manufacturer, we support a variety of models, such as Toyota HILUX HIACE 4RUNNER FORTUNER TACOMA LAND CRUISER PRADO; Mitsubishi FUSO/CANTER; Hino Truck; Isuzu Truck NPR NKR NHR FRR FSR FTR; Nissan PATROL; BMW differential;

We also support customized design requirements and can design solutions according to customer needs. If you need to know more models, please contact us.

Why choose HY

Brand new products: HY is a professional Automotive Differential Supplier, all products are brand new, and the quality and durability are guaranteed.

About sample policy: We support providing samples for quality testing, and only need to pay the sample fee.

About warranty: Usually the warranty period is 12 months, and 24-hour online after-sales service.

About quality inspection system: We can support material chemical composition testing, UT testing, hardness, mechanical properties testing (impact testing, yield strength testing, tensile strength testing), size testing and other reports according to the actual needs of customers.