China Die-cast auto parts manufacturer Manufacturers, Suppliers, Factory

We believe that extensive time period partnership can be a result of top quality, price added support, loaded encounter and personal contact for Die-cast auto parts manufacturer,bmw differential,350z differential,hellcat differential,chevy differential, Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software advancement are our distinguishing feature.

Die-cast auto parts manufacturer, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

Hot Products

Casting Gearbox Components

Jiangjun Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.Gaming Keyboard

HY is a manufacturer of gaming mechanical keyboards. The stamped gaming keyboard produced is a high-end product specially designed for gamers, aiming to create the most accurate, comfortable and efficient gaming experience for players. Made with high-quality materials and advanced technology, this keyboard is both durable and high-performance.Coffee Machine Filter

Product name: Die-cast coffee machine filter accessories

Surface treatment: polished

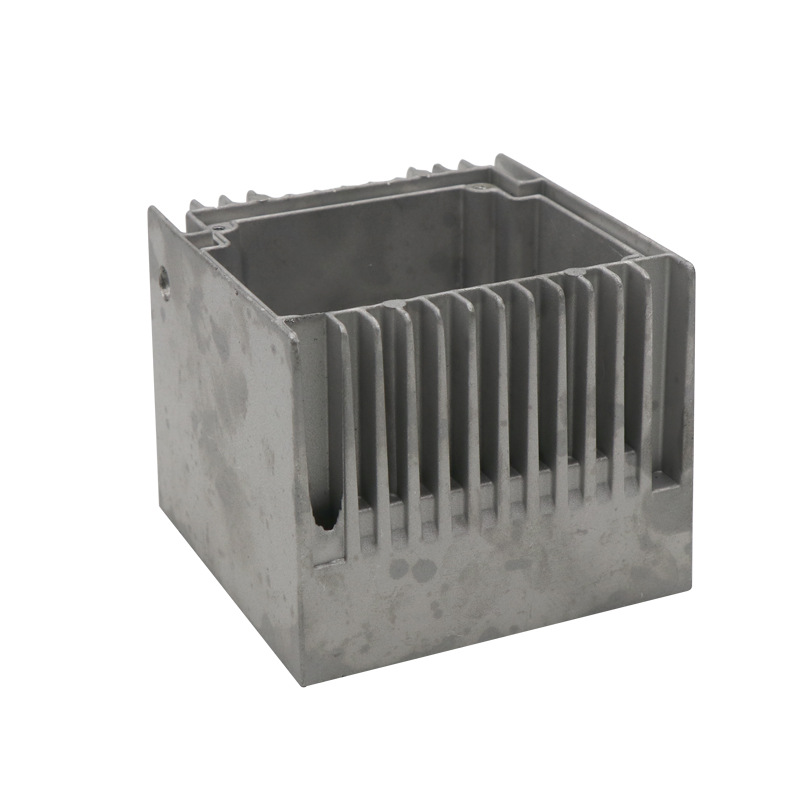

Manufacturing process: precision castingDie Casting Main Housing

At HY, we ensure high-speed production of Die Casting Main Housing in a wide range of sizes, shapes and configurations.Jiangjun is a first-class manufacturer and supplier in the Die Casting Main Housing.Brake Handle

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional die-cast brake handle factory with good product quality and low price. HY has independent R&D and manufacturing capabilities, and attaches great importance to quality control. Our products have obtained CE, FCC, and RoHS certifications.

Bike brake handle manufacturing process: metal mold casting

Surface treatment: sandblasting, powder spraying

Material: aluminum alloy

Tolerance: 0.1mm

Proofing cycle: 3-7 daysCasting Medical Gas Outlet

HY is a factory qualified for the production of medical gas outlet for export.Casting medical gas outlet should be gas-specific with a gas-specific indexing pin arrangement to connect the lock valve assembly only to the specifically matched gas back body, preventing interchangeability of gas services.