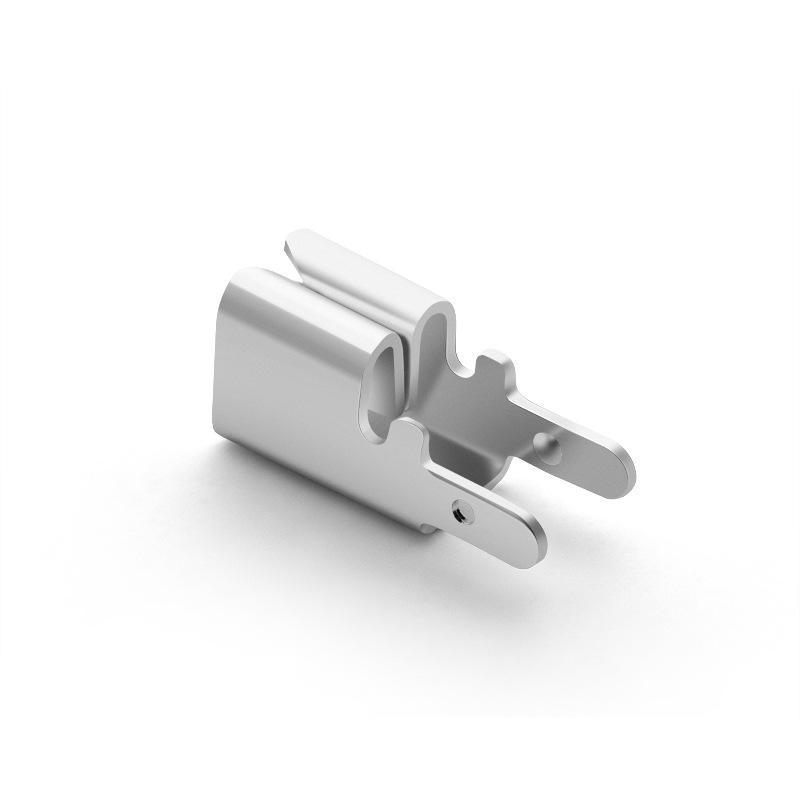

machine screws

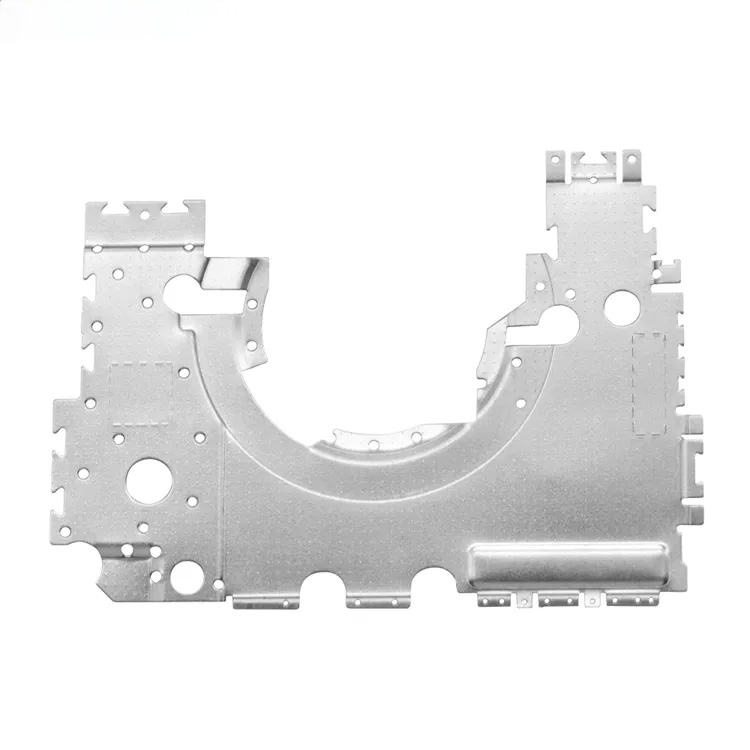

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of machine screws fasteners, focusing on different series of fastener products, including stainless steel and carbon steel nuts, screws, bolts, washers and various stamping and die-casting products. Based on our own production capacity, we can provide one-stop product services such as design, customization, production and after-sales according to your needs.

Thread size: M6/M8//M10/M12/M14/M16/More

Surface treatment: galvanized/other

Material: stainless steel

Standard: ISO8677, DIN603, GB14

Send Inquiry

Machine screws connection has become the most widely used connection method in mechanical equipment with its economic, reliable and fast advantages.

Threaded connection involves the hole specifications of the connecting parts, the screw insertion depth, drilling depth, tapping depth of various materials, and there are clear recommended parameters for blind holes, through holes, etc.

The quality problems that may occur in the quenching and tempering process of machine screws are mainly: insufficient hardness in the quenching state, uneven hardness in the quenching state, excessive quenching deformation and quenching cracking. Such problems that occur on site are often related to raw materials, quenching heating and quenching cooling. Correctly formulating heat treatment processes and standardizing production operation processes can often avoid such quality accidents.

The production of machine screws needs to ensure both the strength of use and the price competitiveness. The heat treatment process has a vital impact on high-strength fasteners, especially its intrinsic quality. Therefore, heat treatment equipment must have large production capacity, high degree of automation and good heat treatment quality.

|

Product name |

machine screws |

|

Material |

Bearing steel, hardened steel, chrome steel, stainless steel |

|

Advantages |

Long life, low noise, low price, high rigidity |

|

Functions |

Anti-friction, dustproof |

|

Applications |

CNC machine tools, motors, lathes, automated machinery, robots, general industrial machinery, automated machinery, electronic machinery, transportation machinery, food machinery, industrial gearboxes, pumps, agricultural machinery...etc. |

Processing technology of machine screws

During the stamping process, the plastic deformation of local areas can reach 60% to 80%. For this reason, the steel selected for machine screws must have good plasticity. When the chemical composition of the material used in machine screws is certain, the metallographic structure is the key factor that determines the quality of plasticity. It is generally believed that thick and flaky pearlite is not conducive to stamping forming, while fine spherical pearlite can significantly improve the plastic deformation of steel. ability.

For medium-carbon steel and medium-carbon alloy steel that use a large amount of high-strength machine screws, spheroidizing (softening) annealing is performed before stamping to obtain uniform and fine spheroidized pearlite to better meet actual production needs.

Why choose HY

Quality is guaranteed, Ping has a strong quality control system to check raw materials, online production and finished products to ensure high quality levels.

Support customized services, have a strong R&D team, and support the construction of complete solutions for customized R&D and production.

Raw material, high hardness, strong and tight, comes with test report, special testing can be carried out according to customer requirements.

Original manufacturer with more than 10 years of production experience providing competitive quality and price.