China front sub frame Manufacturers, Suppliers, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for front sub frame,subframe,rear subframe,subframe car,front subframe, Our goods are strictly inspected before exporting , So we gain a excellent standing all around the planet. We wanting ahead to cooperation with you in the foreseeable future.

front sub frame, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Hot Products

Stamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing partsEngine Turbocharger

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysMotor Base

Xiamen Jiangjun Intelligent Technology Co., Ltd. has always adhered to the business policy of production specialization, product branding, market internationalization, and global layout, and supplies Motor Base and other Precision aluminum casting to domestic and foreign markets and customers with high-quality products.

Product name: Motor Base

Application: Smart home, construction machinery, servo motor

Customization: Support pricing processing servicesPaint Spoon

Product name: Hardware stamping paint spoon

Material: carbon steel plate

Mold: multi-process continuous mold

Processing size: 66.3*34*10 (mm)

Process: cutting, forming, deep drawing, cold extrusionstroller frame for car seat

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, etc.

Processing technology: metal die-castingbattery trays

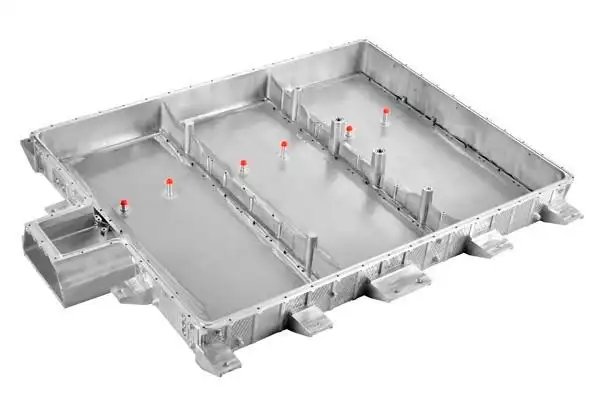

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customized