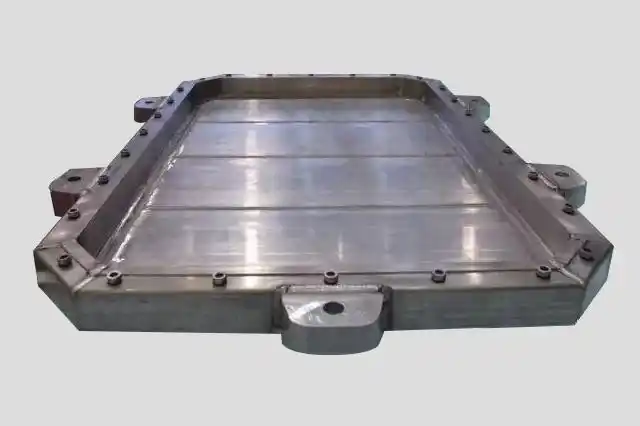

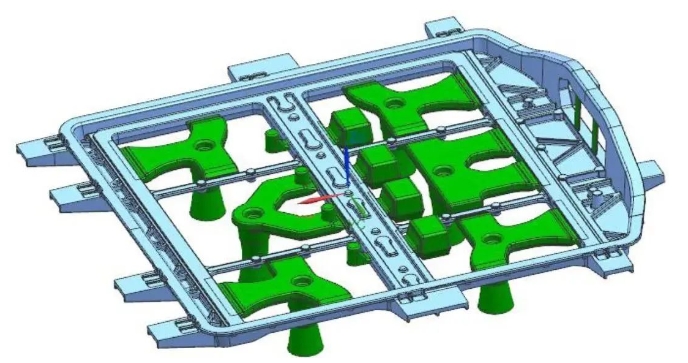

battery trays

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customized

Send Inquiry

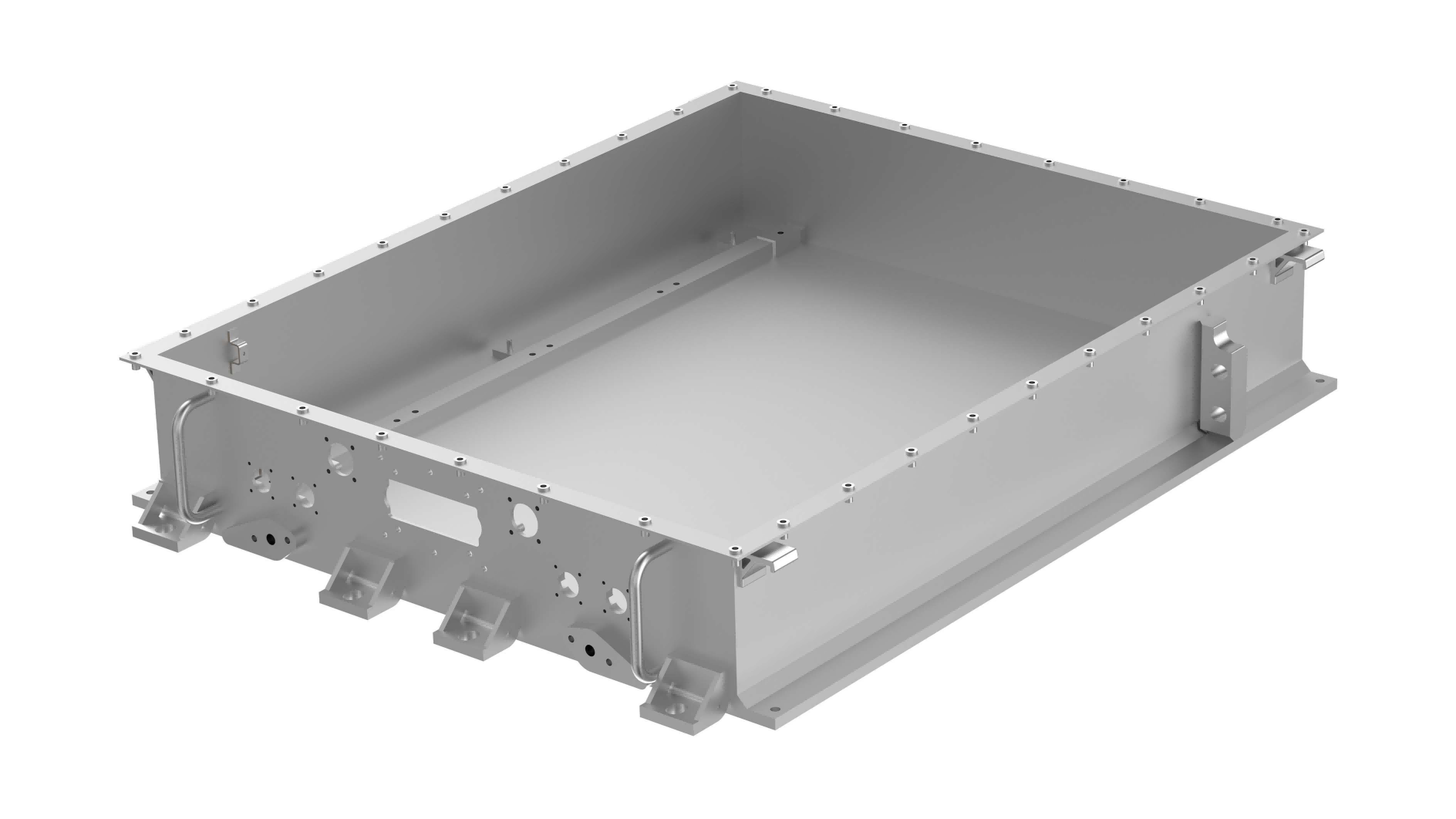

Battery trays are an important part of lithium battery energy storage systems and a core component of new energy vehicles. In the battery module, the car battery holder is the main component that plays the role of bearing, protection and heat dissipation. The modular battery pack is arranged in the battery tray and fixed to the chassis of the car through the battery tray.

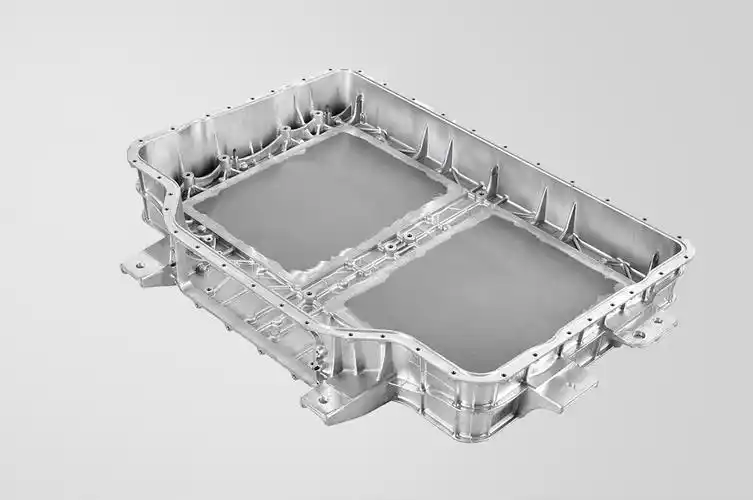

Processing technology of battery trays

Because the battery is installed at the bottom of the car body and the working environment is harsh, the battery tray needs to have the function of preventing stone impact and puncture to prevent the battery module from being damaged. The battery tray is an important safety structural part of electric vehicles. Next, HY will briefly introduce the molding process and mold design of aluminum alloy battery trays for electric vehicles.

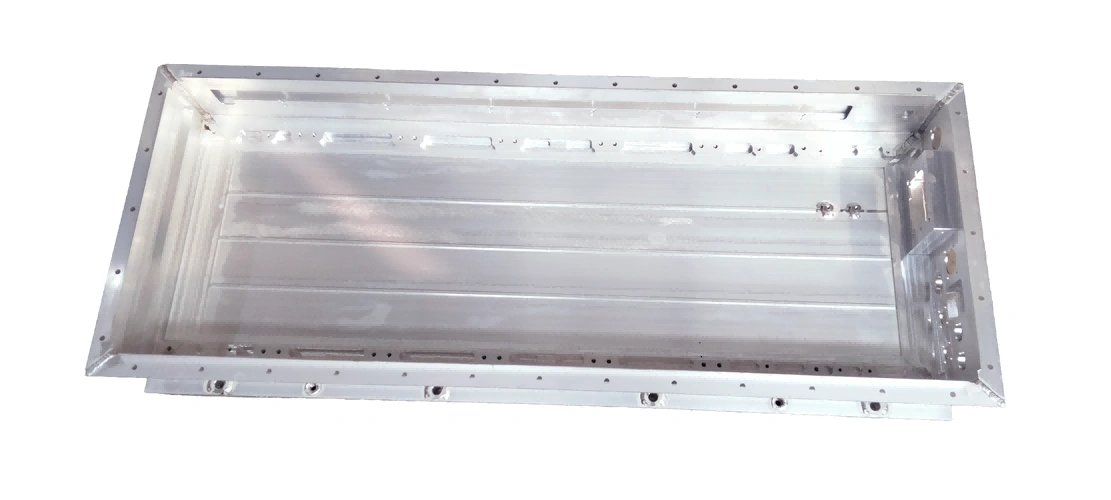

HY uses low-pressure casting to produce castings of aluminum alloy battery trays for electric vehicles. Compared with pressure casting and gravity casting, low-pressure casting has the advantages of using metal molds and the characteristics of stable filling.

In view of the large and thin size of the casting, multiple gates need to be designed. At the same time, in order to ensure smooth filling of aluminum liquid, a filling channel is added at the window, which needs to be removed in the later processing.

At the same time, overflow risers are added, which is conducive to the filling of aluminum liquid and reduces or avoids defects in molded castings. The main stress-bearing parts and areas with high mechanical performance requirements of the battery tray need to be reasonably designed to avoid shrinkage or thermal cracking. The basic wall thickness of the casting is at least 4mm to ensure strength and durability.

Development trend of battery trays

As the largest new energy consumer market and the first-tier R&D and production market, China has strong technical reserves and iterative competitive pressure. Therefore, China's new energy independent brand manufacturers are more competitive in the new energy vehicle tray industry.

The downstream customer base of new energy vehicle battery tray manufacturers is mainly new energy vehicle or power battery companies. Customized optimization of product attributes leads to strong customer stickiness of battery tray manufacturers.

Lightweighting of automobiles is a major development trend in the later period after the maturity of the automobile industry. This highlights new requirements for the production materials and structural design of battery trays. In terms of production materials, the current usage rate of aluminum alloy in battery trays has exceeded 80%, which can be declared to have replaced ordinary steel as the main material for battery trays.

In addition to aluminum alloy, the use of composite materials such as magnesium alloy and carbon fiber in the production of car battery holders is also the current direction, but the process of other materials is complicated and the cost is high. They have not yet been mass-produced, and aluminum is still the main material.

Why choose HY

Xiamen Jiangjun Intelligent Technology Co., Ltd. was founded in 2017. From a small start, we have grown into one of the well-known import and export marine/automotive wholesalers in China. HY provides distribution services to marine retailers, auto parts retailers, camper manufacturers, boat manufacturers, outdoor goods retailers, docks, marine electricians and all general marine and automotive electrical parts traders.

HY supports OEM/ODM customized production, and always conducts final inspection before shipment to ensure that customers receive products with no problems.

Fast delivery, most projects can be delivered within 8-20 days, and OEM projects are determined according to your specific needs.

HY has strict quality control, after order confirmation, specifications-materials-production line operations-before packaging-after packaging and before loading, our QC is 7/24.