China Die cast metal lampshade Manufacturers, Suppliers, Factory

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for Die cast metal lampshade,casting aluminum,aluminum die casting manufacturer,die cast metal,aluminum die casting, We have been prepared to offer you the top suggestions on the designs of one's orders in a professional way if you need. During the meantime, we retain on developing new technologies and building new designs so as for making you ahead within the line of this business.

Die cast metal lampshade, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions and ideas with us!!

Hot Products

Meat Grinder Screw

As a leading manufacturer of meat grinder die-casting parts, HY specializes in the production of high-quality meat grinder screws. HY's screws provide precision and efficiency while ensuring perfect grinding every time. Our meat grinder screws are made of high-quality materials, making them durable and reliable even in the most demanding conditions.Stamping Photovoltaic Terminals

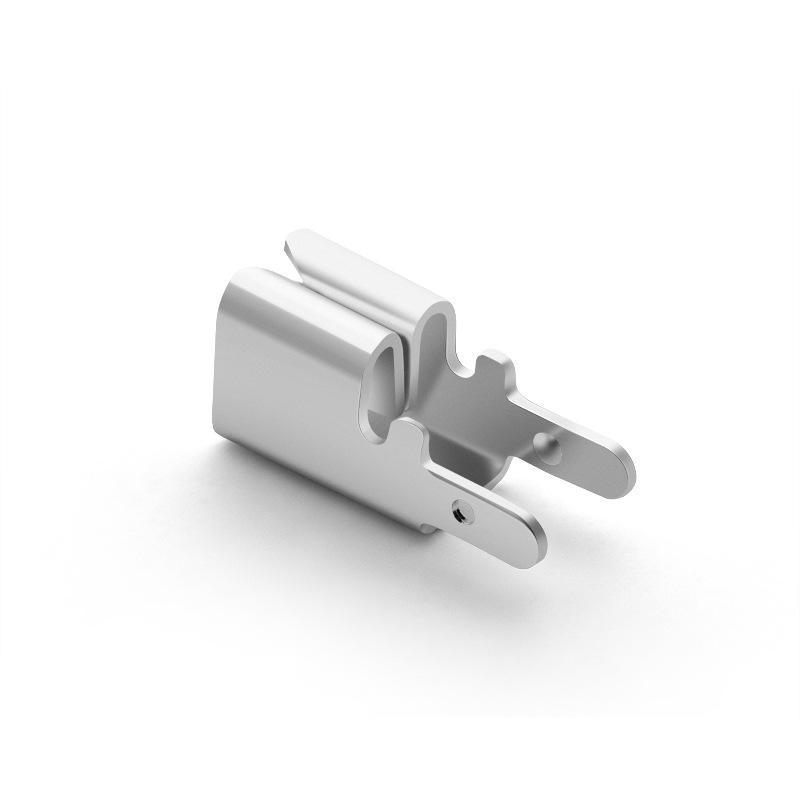

Welcome to wholesale Stamping Photovoltaic Terminals from us,every request from customers is being replied within 24 hours. HY is a factory that specializes in customizing the production of photovoltaic terminal .The photovoltaic terminals of a photovoltaic system inverter are vital electrical connectors used to establish connections between the inverter and the various components of the photovoltaic (PV) system. They play an important role in ensuring efficient and reliable power transmission within the system.spring washers

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a leading manufacturer and supplier of spring washers fasteners. Over the years, we have served many customers in North America, Europe, Oceania and the Middle East, and our quality and fast delivery have been praised by many customers. HY has passed IS09001:2015 international quality management system certification, IATF16949:2016 automotive industry quality management system certification and IS014001:2015 environmental management system certification.

Application scenarios: mining, healthcare, retail industry, industrial machinery, oil and gas, automotive industry

Product type: belleville washer/spring washers

Surface treatment: black, galvanized, other customization

Material: stainless steel, aluminum, special requirements

Processing technology: stampingelectric hospital bed

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a comprehensive medical care enterprise covering R&D, production, sales and after-sales service. It combines processing technology with national environmental certification materials and has a series of product production lines covering intermediate care beds, operating beds, electric hospital beds, etc. HY is committed to promoting medical care into an era of intelligent innovation, giving patients and medical staff more health and humanistic care.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: electric hospital bed

Product use: hospital home furniture nursing bed

Product application scenario: hospital, nursing homeEngine Turbocharger

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysGalvanized Male And Female Stamping Parts

Jiangjun is a factory that uses stamping to Galvanized Male And Female Stamping Parts. Metal stamping uses progressive high speed stamping Die and specialized presses and feeders to cut and form galvanized male and female parts from coils of steel. The metal stamping process is fast and efficient, making it ideal for mass production of metal parts.