China casting aluminum Manufacturers, Suppliers, Factory

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for casting aluminum,custom heatsink,aluminum heat sink,led heat sink,extruded heat sink, Created merchandise with brand price. We attend seriously to produce and behave with integrity, and via the favor of buyers at your house and overseas inside the xxx industry.

casting aluminum, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Hot Products

electric hospital bed

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a comprehensive medical care enterprise covering R&D, production, sales and after-sales service. It combines processing technology with national environmental certification materials and has a series of product production lines covering intermediate care beds, operating beds, electric hospital beds, etc. HY is committed to promoting medical care into an era of intelligent innovation, giving patients and medical staff more health and humanistic care.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: electric hospital bed

Product use: hospital home furniture nursing bed

Product application scenario: hospital, nursing homemedical tweezers

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steelCamera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.Meat Grinder Screw

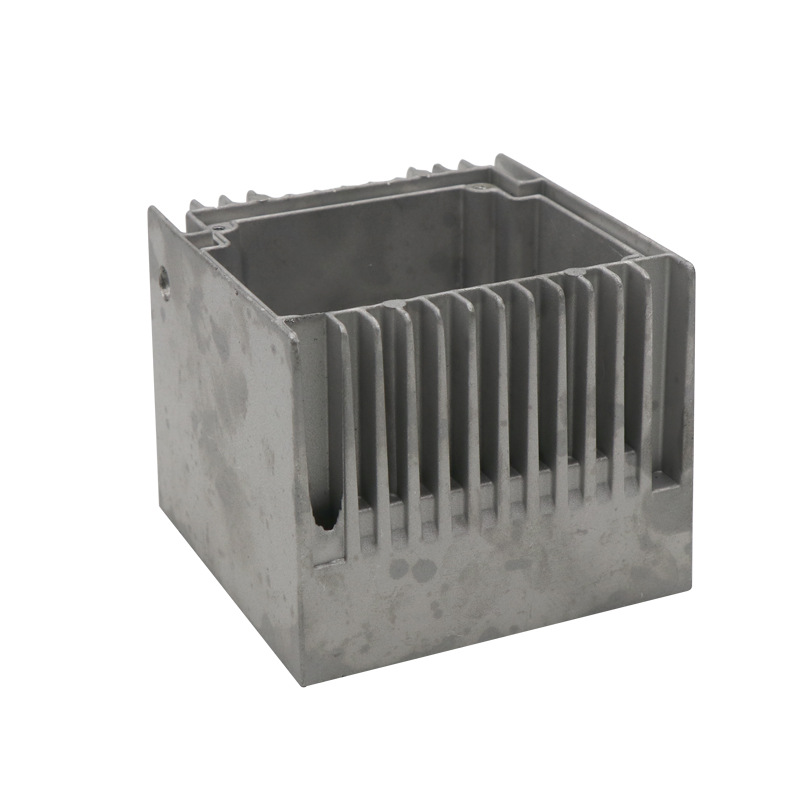

As a leading manufacturer of meat grinder die-casting parts, HY specializes in the production of high-quality meat grinder screws. HY's screws provide precision and efficiency while ensuring perfect grinding every time. Our meat grinder screws are made of high-quality materials, making them durable and reliable even in the most demanding conditions.Precision Metal Aluminum Casting Housing

The Precision Metal Aluminum Casting Housing is carefully crafted with state-of-the-art technology to ensure precision and excellence. We take pride in our manufacturing process, which is overseen by experienced and skilled professionals who ensure that our products meet and exceed industry standards.Aluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 days