China car seat chassis Manufacturers, Suppliers, Factory

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for car seat chassis,elite car seat carrier,steel frame car seat,stroller frame for car seat,car seat carrier frame, We glance ahead to supplying you with our goods from the near long run, and you'll find our quotation is very acceptable plus the top quality of our goods is quite outstanding!

car seat chassis, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we have been looking forward to the mutual cooperation with all friends at home and abroad and we'll create a bright future of business.

Hot Products

Metal Stamping Electronic Wire Assemblies

HY is a Metal Stamping Electronic Wire Assemblies factory that custom-processes metal stamped electronic wire assemblies.The industries served by HY include home appliances, electrical equipment, electronics, and lighting. Nearly 20 years of experience in Precision Metal Stamping.battery trays

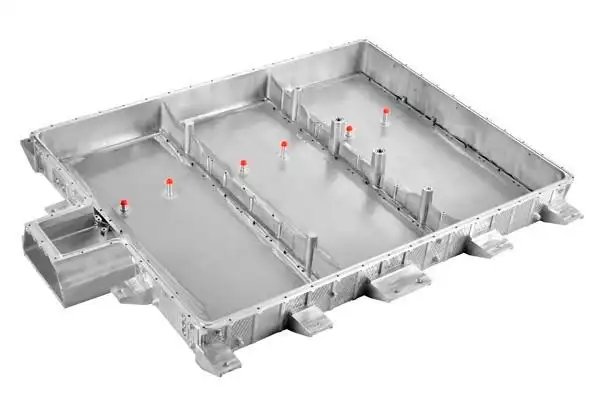

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customizedGalvanized Male And Female Stamping Parts

Jiangjun is a factory that uses stamping to Galvanized Male And Female Stamping Parts. Metal stamping uses progressive high speed stamping Die and specialized presses and feeders to cut and form galvanized male and female parts from coils of steel. The metal stamping process is fast and efficient, making it ideal for mass production of metal parts.spring washers

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a leading manufacturer and supplier of spring washers fasteners. Over the years, we have served many customers in North America, Europe, Oceania and the Middle East, and our quality and fast delivery have been praised by many customers. HY has passed IS09001:2015 international quality management system certification, IATF16949:2016 automotive industry quality management system certification and IS014001:2015 environmental management system certification.

Application scenarios: mining, healthcare, retail industry, industrial machinery, oil and gas, automotive industry

Product type: belleville washer/spring washers

Surface treatment: black, galvanized, other customization

Material: stainless steel, aluminum, special requirements

Processing technology: stampingStainless steel mixing bowl

Product name:Stainless Steel Mixing Bowls, Usage:Kitchen Home Hotel Restaurant, Logo:Customized Logo Acceptable, Production process: metal stamping,Aluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 days