solar panel mounting system

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company that mainly manufactures photovoltaic modules and photovoltaic brackets. It mainly produces high-power 550-730 watt photovoltaic modules and photovoltaic brackets. HY is mainly engaged in the design and production of rooftop and ground solar photovoltaic installation solutions. Related products include stainless steel roof hooks, aluminum alloy roof brackets, aluminum alloy solar panel clamps, steel ground screws, etc.

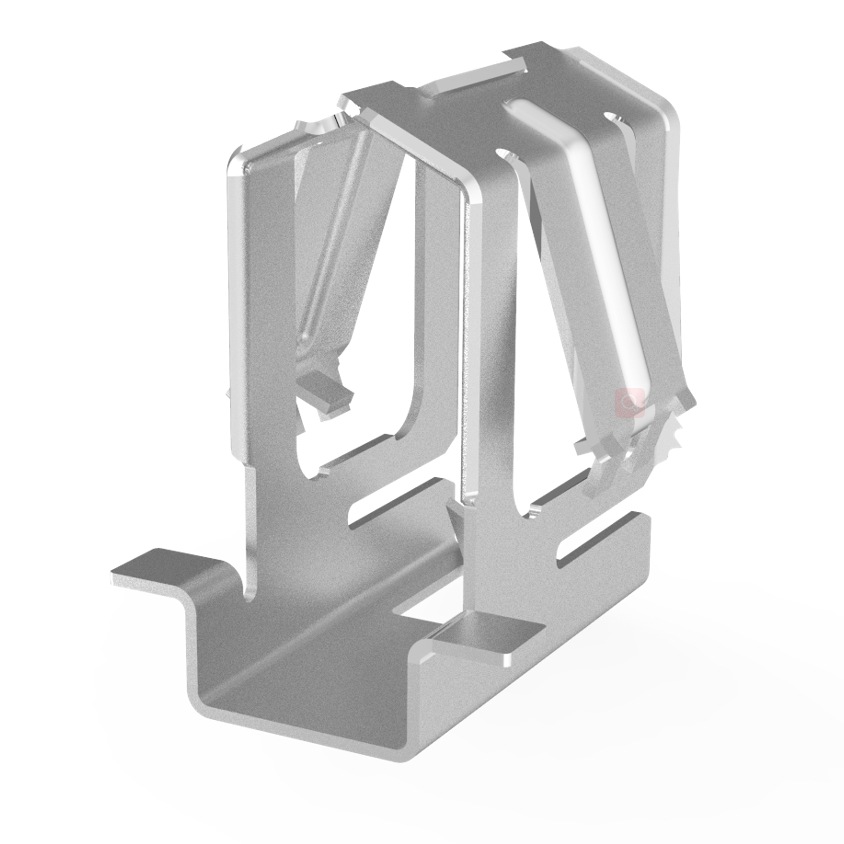

Product type: solar panel mounting system, solar panel pole mountr

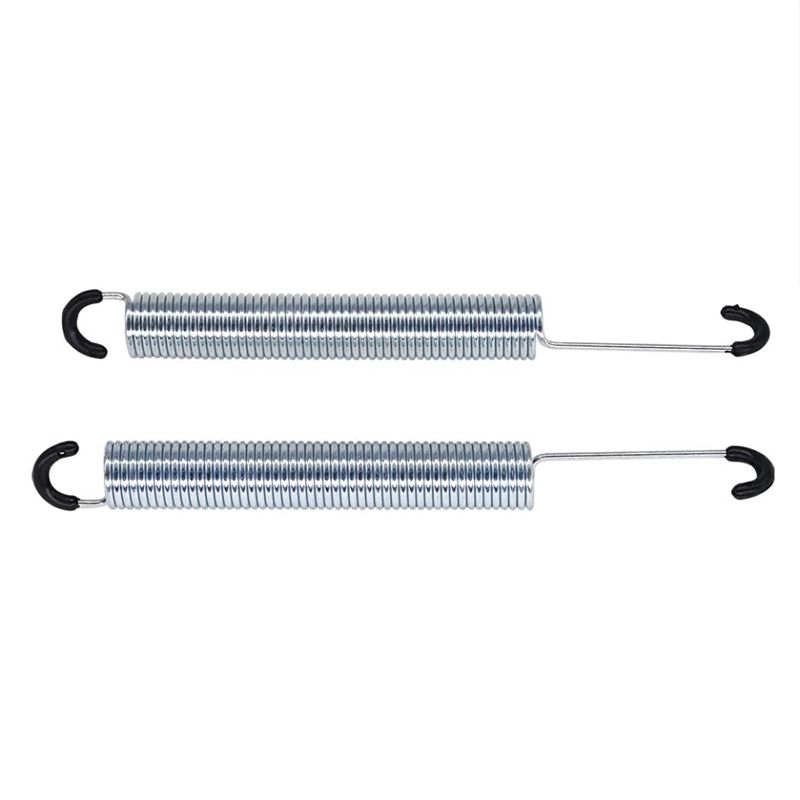

Processing services: stamping, die casting, bending, welding, punching, cutting

Material: aluminum alloy, stainless steel

Service life: 20-25 years

Send Inquiry

Solar panel mounting system is a special bracket designed for placing, installing and fixing solar panels in solar photovoltaic power generation systems. The general materials are aluminum alloy, carbon steel and stainless steel.

Material selection and process flow of solar panel mounting system

HY's solar panel mounting system starts with material selection, using high-quality steel and aluminum alloy, and then forms the various components of the bracket through precision cutting, bending and stamping. In this link, precision is the key, and any slight dimensional deviation may affect the stability of the overall structure.

All parts are stamped and connected using welding technology. The combination of automated welding and manual fine welding requires ensuring that the weld is firm and the appearance is smooth. During the welding process, the temperature and speed must be strictly controlled to avoid deformation or cracking of the material caused by overheating.

The solar panel mounting system also needs to undergo anti-corrosion treatment, including hot-dip galvanizing, plastic spraying and other processes, which can effectively improve the corrosion resistance of the bracket and extend its service life. It should be noted that before surface treatment, ensure that the surface of the bracket is clean and oil-free, otherwise it will affect the anti-corrosion effect. It is guaranteed to be rust-free for 20 years of outdoor use.

|

Product Type |

Solar panel pole mountr, photovoltaic accessories, stamping parts |

|

Standards |

DIN, ASTM/ANSI JIS EN ISO, AS, GB |

|

Surface treatment |

Zinc (yellow, white, blue, black), hot dip galvanized (HDG), black, Geomet, Dacroment, anodized, nickel plated, zinc nickel plated |

|

Snow load |

1.4KN/m2 |

|

Wind load |

60m/s |

HY Product Advantages

The links and load-bearing between the components are scientifically designed and accurately calculated, which fully guarantees the mechanical strength of each component.

High-quality materials can effectively prevent sand, dust, rain and snow erosion, enhance service life, and effectively cope with extreme climates.

The anti-shadow design effectively avoids the problem of shadow blocking in the morning and evening, effectively increasing power generation.

Reliable and firm design ensures long-term reliability and easy maintenance.

Why choose HY

Strict quality control: From material selection to finished products, every link must strictly control quality to ensure accurate dimensions, firm welding, and effective anti-corrosion. After the goods are completed, HY can provide you with MTC and factory certificates.

Durable structure: This product adopts hot-dip galvanized surface treatment, providing strong and durable long-lasting protection against corrosion and harsh environmental conditions.

Free sample policy: For new customers, we can provide free samples for standard fasteners, but the customer will pay the courier fee. For old customers, we will send you free samples and pay the courier fee by yourself.

OEM and ODM services: Yes, HY accepts OEM and ODM orders, and welcomes customers to inquire.

Professional technical connection: When sending an inquiry, please provide drawings, specifications, quantity and/or more of the samples provided, and professional technicians will connect with you online.