China steel stamp Manufacturers, Suppliers, Factory

The key to our success is "Good Merchandise High-quality, Reasonable Selling price and Efficient Service" for steel stamp,hot stamping foil,stamping dies,progressive dies,cold stamping, Should further more info be required, remember to call us at any time!

steel stamp, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our items, make sure you do not hesitate to contact us, we'll be happy to provide you with further information!

Hot Products

stainless steel lid

HY's stainless steel lid is a high-quality product made of high-quality 304 stainless steel. With its excellent strength and durability, it is ideal for sealing a variety of jars or bottles. HY's advanced stamping process ensures that the lid is seamless, well-formed and void-free, making it extremely corrosion-resistant. This production design makes it a versatile product that can be used in a wide range of applications from kitchen utensils to industrial containers.Engine Turbocharger

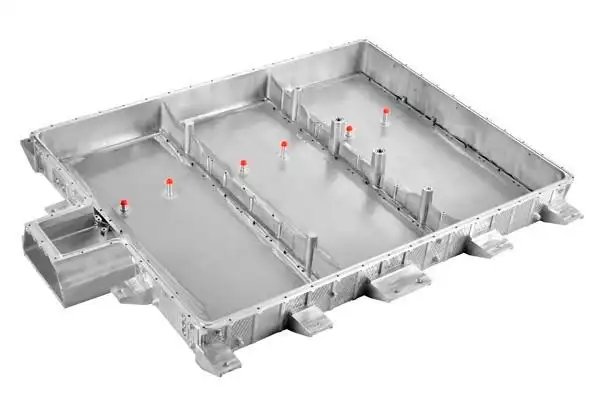

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysCasting Medical Valve

HY is a medical valve factory from China. Casting Medical Valve is used to change the channel cross-sectional area and medium flow direction. It has functions such as diversion, cut-off, regulation, throttling, check, diversion or overflow pressure relief. Medical valve castings are control components in pipeline fluid delivery systems. Quality Control: 100% QC Inspection

Certification: ISO9001/CE/ROHS

Size: Support OEM/ODM customizationMedical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentAluminum Die Casting Flashlight Lighting

HY is a factory that Aluminum Die Casting Flashlight Lighting high-precision stamping and die-casting.Die casting has proven to be an effective method of producing different parts using different materials: copper, zinc and aluminum alloys. Aluminum die casting various properties make it a good metal for die casting.Aluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 days