China Die cast chassis supplier Manufacturers, Suppliers, Factory

To continually improve the management procedure by virtue in the rule of "sincerely, great religion and good quality are the base of company development", we commonly absorb the essence of associated products and solutions internationally, and regularly build new solutions to meet the calls for of consumers for Die cast chassis supplier,chassis paint,go kart frame,chassis saver,stallard chassis, We are really proud of your great name from our shoppers for our products' reputable quality.

Die cast chassis supplier, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent for you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

Barbecue Grill

Xiamen Jiangjun Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business.

Stamping type: metal stamping processing

Grill material: stainless steel plate

Processing type: metal forming

Process: stamping, bending, trimming, forming, blanking

Surface treatment: electroplating

Proofing cycle: 8-15 daysStamping Busbars

HY is a factory that produces progressive high-speed Stamping Busbars.Stamping Busbars is a key component of electric vehicles, and copper, brass and aluminum are the three most common busbar materials. Busbars are most commonly used in three-phase power distribution systems.bmw license plate frame

Xiamen Jiangjun Intelligent Technology Co., Ltd. specializes in providing customers with local standard license plate frames, such as bmw license plate frame, American standard and European license plate frames, custom car plate frames, with 17 years of processing experience, can provide you with high quality and good service.

Material: metal, stainless steel, aluminum alloy, plastic

Application: auto parts, truck parts

Customized service: support customizationZinc Die-Cast Door Handle

Product name: Precision machining of zinc die-cast door handle

Material: Zinc alloy

Product Name: Precision machined zinc die-cast door handle

Usage: Train door handles, construction decoration door handles

Sample: 42 days for mold opening + proofingMedical Equipment Base

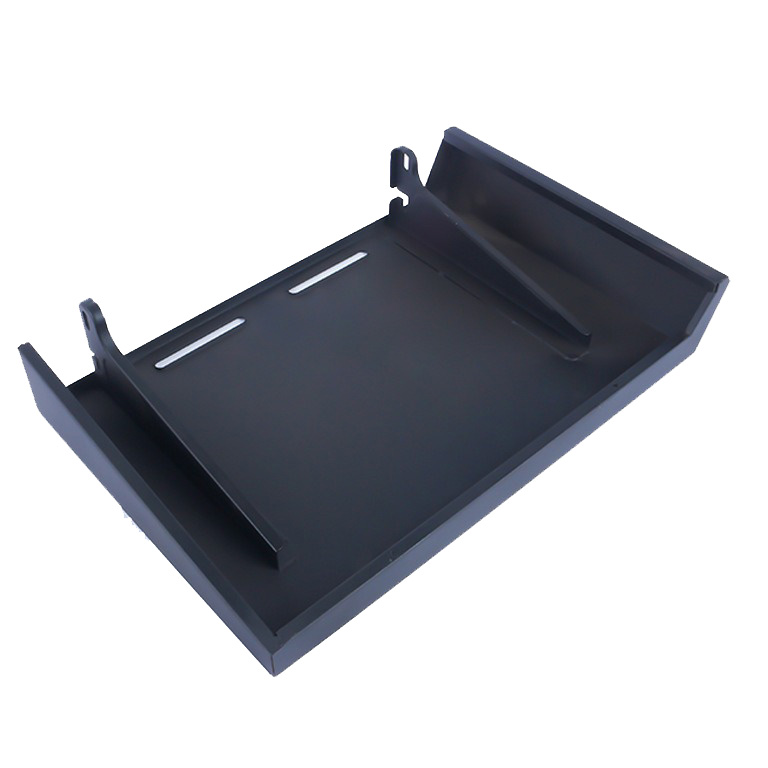

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

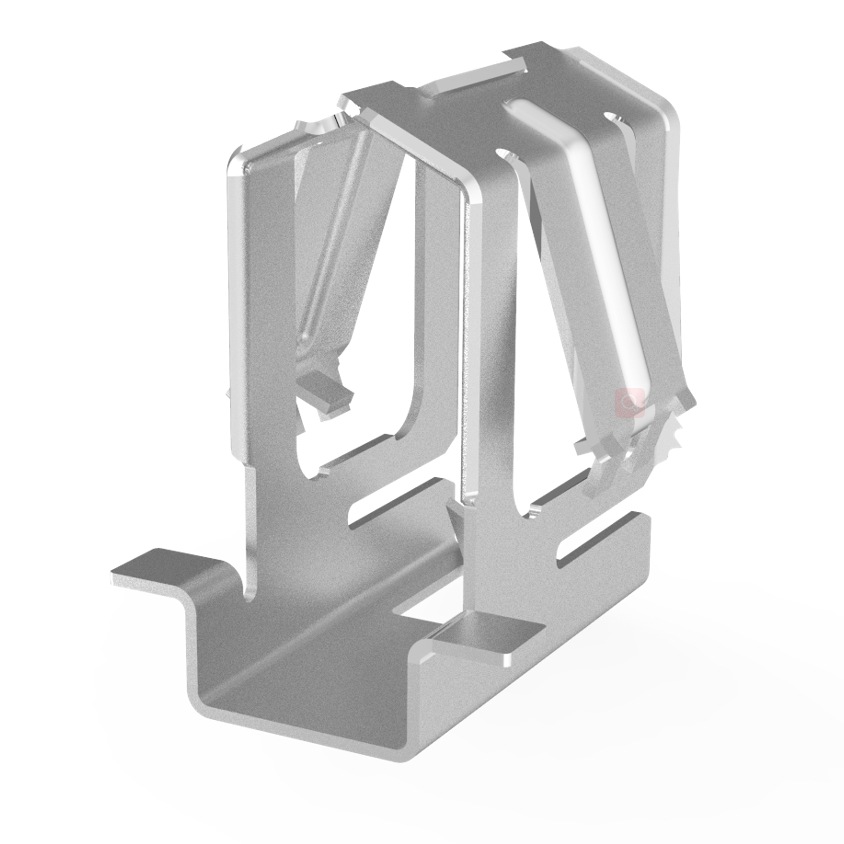

Application areas: medical equipment automation equipmentAluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 days