China car exhaust pipe Manufacturers, Suppliers, Factory

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for car exhaust pipe,exhaust pipe,vance and hines exhaust,exhaust flange,stainless exhaust tubing, We goal at Ongoing system innovation, management innovation, elite innovation and sector innovation, give full play for the overall advantages, and constantly make improvements to support excellent.

car exhaust pipe, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

Hot Products

hospital beds

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of medical care equipment. HY produces a wide range of products with a complete import and export qualification system. Its products are exported to Europe, the United States, the Middle East and other regions, including hospital beds, multi-functional nursing beds, electric beds, manual beds, outpatient beds, massage beds, walkers, etc. We welcome customers from all over the world to visit.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: hospital beds

Product use: hospital home furniture nursing beds

Product application scenarios: hospitals, nursing homes, familiesStainless steel mixing bowl

Product name:Stainless Steel Mixing Bowls, Usage:Kitchen Home Hotel Restaurant, Logo:Customized Logo Acceptable, Production process: metal stamping,Zinc Die-Cast Door Handle

Product name: Precision machining of zinc die-cast door handle

Material: Zinc alloy

Product Name: Precision machined zinc die-cast door handle

Usage: Train door handles, construction decoration door handles

Sample: 42 days for mold opening + proofingBarbecue Grill

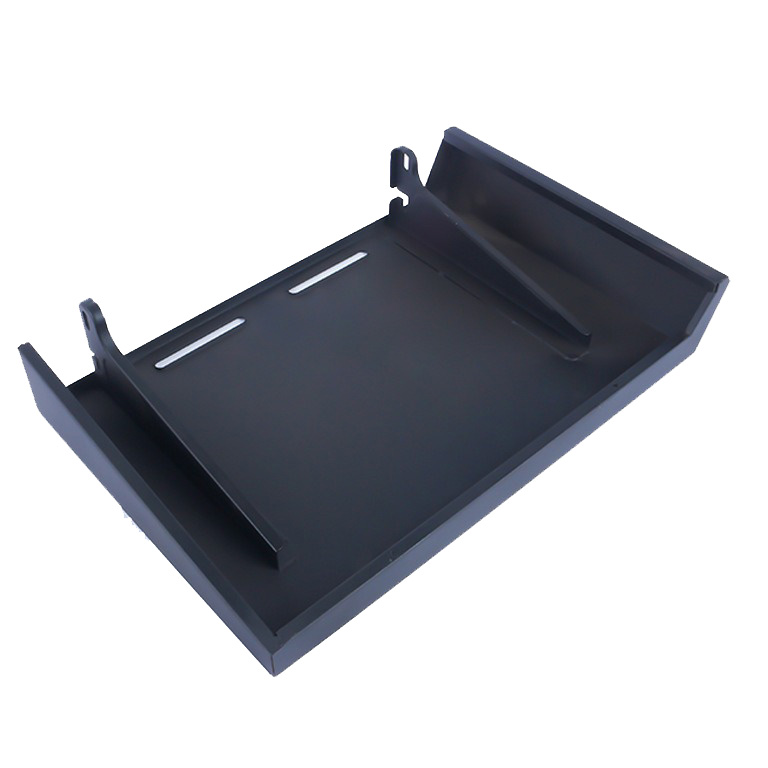

Xiamen Jiangjun Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business.

Stamping type: metal stamping processing

Grill material: stainless steel plate

Processing type: metal forming

Process: stamping, bending, trimming, forming, blanking

Surface treatment: electroplating

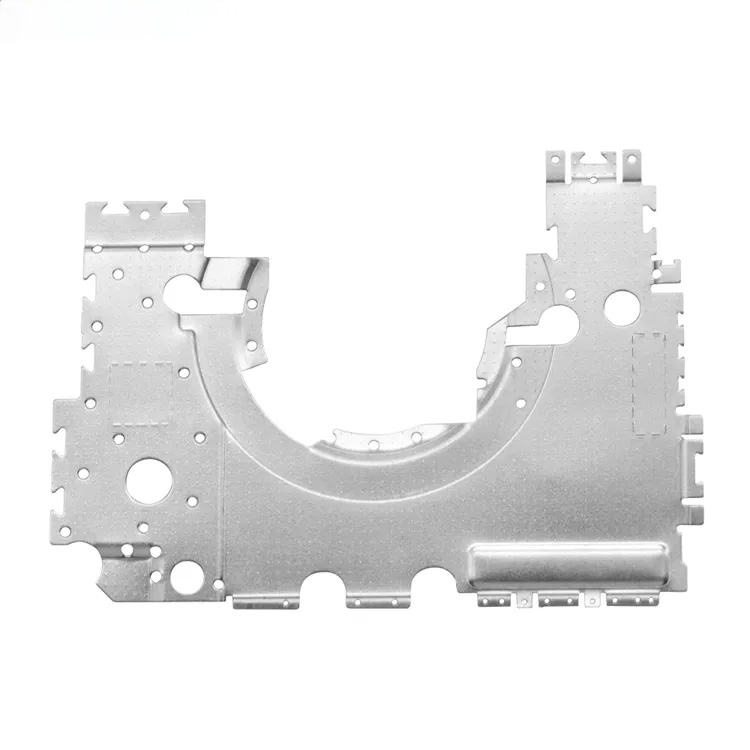

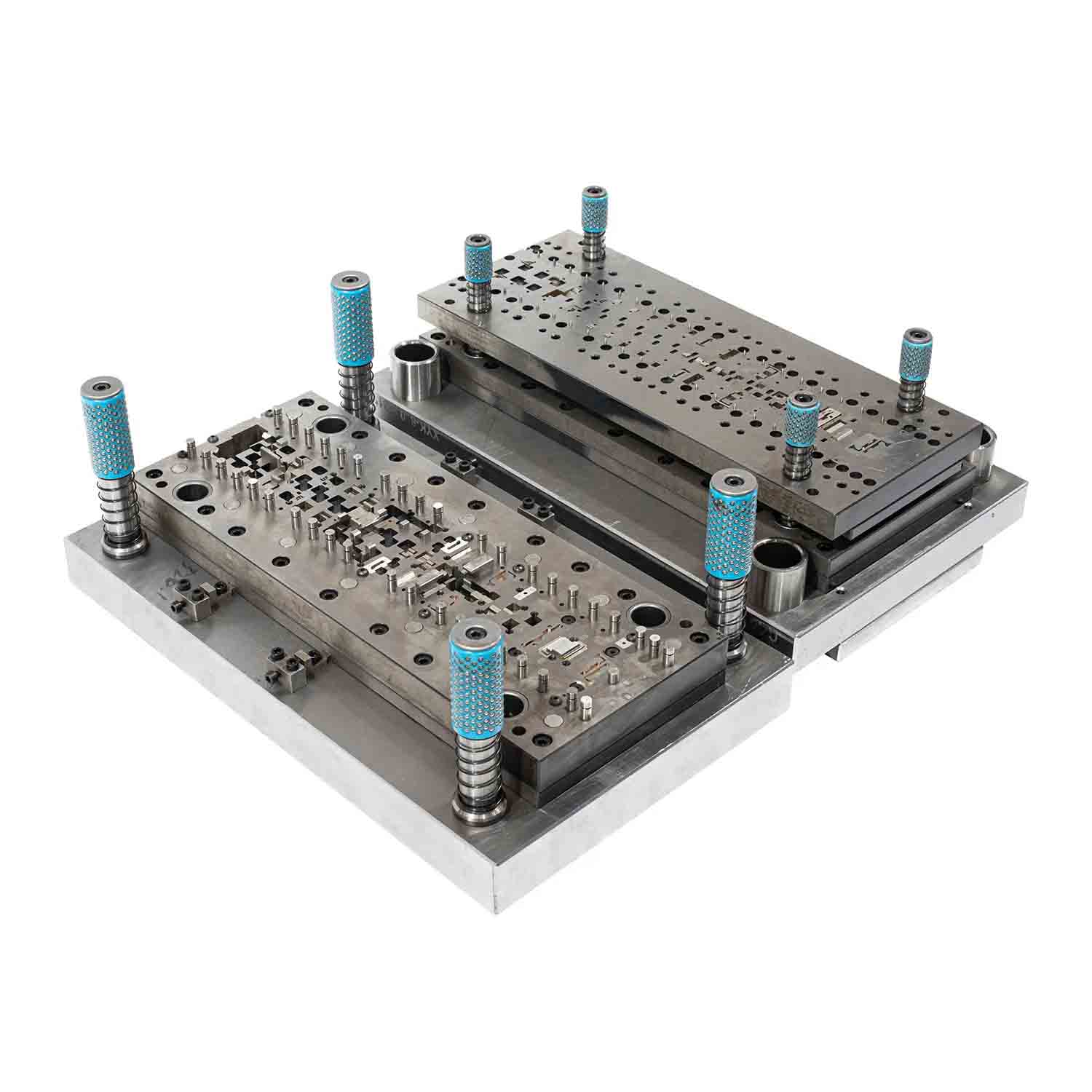

Proofing cycle: 8-15 daysCustom Metal Stamping Dies

Xiamen Jiangjun Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.Brake Handle

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional die-cast brake handle factory with good product quality and low price. HY has independent R&D and manufacturing capabilities, and attaches great importance to quality control. Our products have obtained CE, FCC, and RoHS certifications.

Bike brake handle manufacturing process: metal mold casting

Surface treatment: sandblasting, powder spraying

Material: aluminum alloy

Tolerance: 0.1mm

Proofing cycle: 3-7 days