China bed in hospital Manufacturers, Suppliers, Factory

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of bed in hospital,hospital beds,bed of hospital,hospital beds for sale,hospital beds for home, Looking to the long run, a lengthy way to go, regularly striving to become the all employees with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced merchandise, good quality first-class modern company and work hard!

bed in hospital, With the enterprising spirit of"" high efficiency, convenience, practicality and innovation"", and in line with such serving guidance of ""good quality but better price, "" and ""global credit"", we're striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

Hot Products

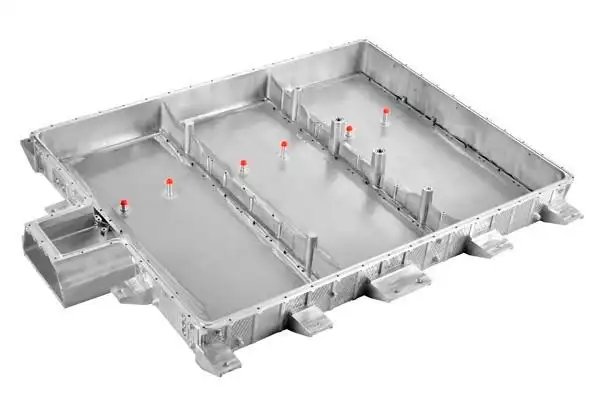

battery trays

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customizedAluminum Die Casting Flashlight Lighting

HY is a factory that Aluminum Die Casting Flashlight Lighting high-precision stamping and die-casting.Die casting has proven to be an effective method of producing different parts using different materials: copper, zinc and aluminum alloys. Aluminum die casting various properties make it a good metal for die casting.Electronic Metal

Xiamen Jiangjun Intelligent Technology Co., Ltd. specializes in aluminum alloy and zinc alloy die-casting processing, and has 17 years of relevant processing experience. HY supports diversified comprehensive services from mold design, manufacturing, and production.

Processing service: Stamping electronic metal accessories

Customization service: Support customization, and can design solutions according to customer needs

Processing type: Metal forming

Tolerance requirement: ±0.02mmhospital screen

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional supplier of hospital screens, hospital beds (manual and electric), hospital stretchers, medical cabinets, hospital trolleys, maternity beds, cribs and other medical care products. HY has a mature import and export system and complete medical certification qualifications. Its current overseas markets include Europe, the United States, the Middle East and other regions.

Color: green, blue, pink, according to demand

Application: hospital, pharmacy, laboratory

Material: stainless steel, waterproof cloth, etc.

Roller: optionalStamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing partsEngine Turbocharger

Xiamen Jiangjun Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 days