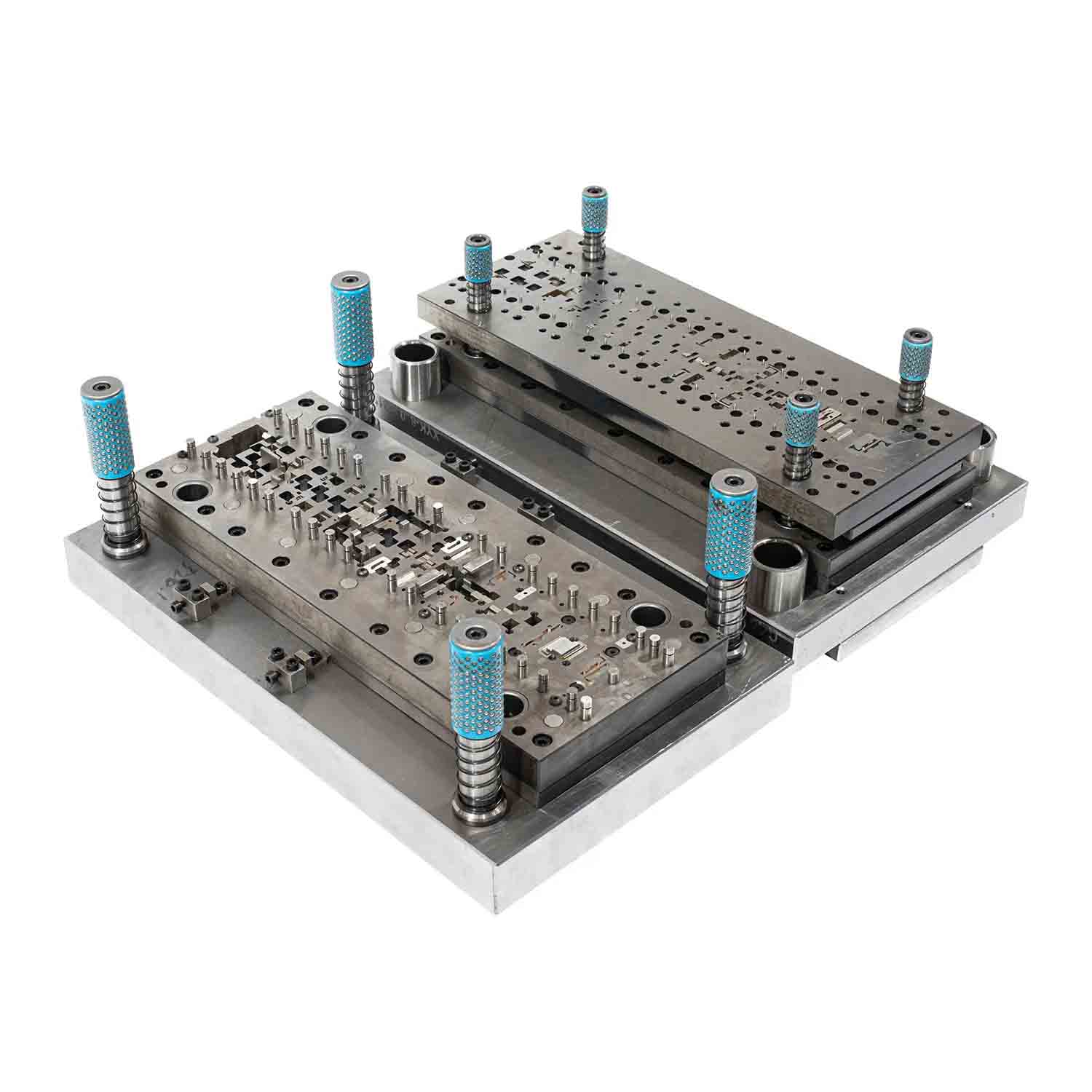

metal phone cases

Xiamen Jiangjun Intelligent Technology Co., Ltd. is an integrated factory of industry and trade. We support the production and customization of metal phone cases. You can provide samples or drawings of metal phone cases. HY has professional mechanical processing and system testing service processes. HY has a complete production line to ensure that it can meet the monthly production capacity needs and provide one-stop services, covering furniture accessories, electronic accessories, medical equipment accessories and other fields. HY is confident to establish long-term cooperation to provide customers with competitive solutions.

ODM service time: It can be completed in 3-5 days at the fastest.

Drawing design service: Support customized design service.

Quality certificate: ISO 9001, ISO14001, REACH, RoHs

Tolerance: 0.02

Send Inquiry

Why can't consumer electronics be without stamping?

Metal products are very common in the consumer electronics industry, such as metal phone cases of smartphones, the appearance structure of TWS headphones, and the overall frame of smart watches. Consumer electronics products have become increasingly lightweight and thin, while also ensuring high strength to meet usage requirements. Metal stamping has become an indispensable manufacturing process for structural design with its advantages of high efficiency, high precision and low cost.

According to existing data, stamping covers at least 80% of the metal case phone parts in a high-end mobile phone.

Core features of stamping

The unit cost will decrease significantly with the production quantity, which is very suitable for mass production of metal phone cases.

Complex geometric shapes can be achieved, including special structures such as curved surfaces and nested structures.

Compared with cutting, the material utilization rate is higher, reaching more than 90%.

Selection of stamping materials, common uses and selection logic.

The stamping materials used in common metal covers for mobile are mainly aluminum alloys, magnesium alloys, stainless steel and other special alloys.

Among them, stainless steel has a lower cost and higher use strength, but it is also the heaviest in use weight. Therefore, it is mainly used in high-precision, high-strength and complex environments, such as medical equipment, or smart watches, etc. Considering the long-term wear of watches, there are requirements such as waterproof, sweat-proof and impact-resistant, so smart watches will also consider using stainless steel, and only a small part is used for steel phone cases.

Magnesium alloys are expensive, so they are often used for some internal accessories that are not impacted, such as the internal structural parts of headphones. Due to the lightness of the material, it can reduce the burden on users.

Special alloys such as titanium alloys are not common material choices, but "the only disadvantage of expensive materials is expensive". They have excellent performance in terms of weight and use strength, and the use cost is higher than that of common materials. Therefore, they are mostly used in high-end luxury or high-precision application scenarios, such as some ultra-thin notebook hinges. When reducing configurations and ensuring use strength, titanium alloys will be considered.

The most common is the aluminum alloy series, which is lightweight, has good strength and a moderate cost. It is widely used in various aspects, including the classic metal iPhone cover, aluminum phone case, drone frame, etc. Aluminum alloy is already the first choice for metal outer frames of various consumer electronics.

The selection of materials can follow three logics:

1. Lightweight design comes first, which is why aluminum alloy is so widely used. Data shows that aluminum alloy accounts for at least 70% of metal phone cases.

2. The art of balancing cost and performance: How to control cost while ensuring performance has always been the main proposition of the mechanical design industry. Therefore, magnesium alloy is mainly suitable for non-stressed decorative parts, and stainless steel is used for key load-bearing structural parts and complex environments.

3. Process adaptability: Special alloys such as titanium alloys require the use of special hot stamping equipment, and the cost is at least 300% higher than that of commonly used materials.

Why choose HY?

The stamping process certainly has unique advantages in the metal phone cover industry, but with the development of the metal mobile cover industry, it also gives the stamping industry many special challenges, which can be roughly summarized as follows.

1. Challenges of industry miniaturization needs: When the stamping aperture on the metal cover mobile phone is ≤1.2mm, it is easy to crack. The current main solution is to use laser pre-punching process.

2. Increased complexity of special-shaped structures: When the complex curvature radius is <0.3mm, it will cause obvious slip lines. The current solution is to use multi-station progressive forming process.

3. Environmental protection requirements: The environmental protection requirements of various countries have increased, which is an important progress for human civilization and the world, but it has brought certain challenges to the cost control of enterprises. However, we are first a part of the world, and then a company, so we actively respond to and support environmental protection indicators, and use a vacuum scrap suction system. The recovery rate of aluminum scraps in the production process of aluminum phone cases can reach more than 98%.

FAQ

About custom colors of metal phone cases: We can customize according to the pantone color card reference you provide, and then send you videos and samples for confirmation, and finally mass production. However, one thing to note is that the printed colors and tones may vary depending on the material, surface and texture.

About metal case phones production progress review: We can provide a detailed production schedule during the production process, and send production reports including digital pictures and videos every week to show customers our processing progress.

About OEM service: We support OEM customization service and can produce according to your drawings or original samples. If you have a design idea, we can also give you some technical suggestions. We can start production after confirming all the details.