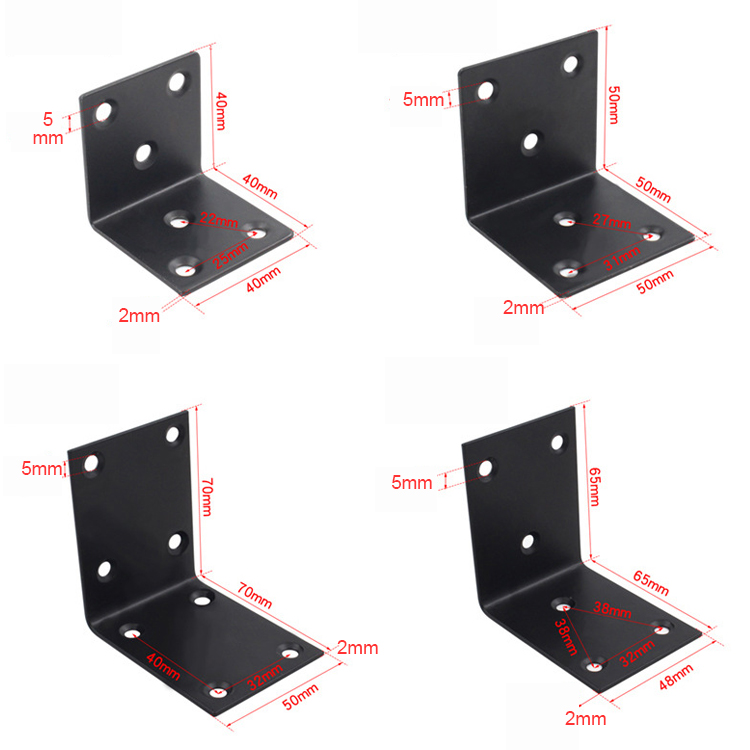

angle bracket

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a company specializing in the manufacture of various metal stamping parts and sheet metal. HY has focused on the research and improvement of relevant technologies and management levels for many years, providing non-standard customized services on high-end hardware products, such as customized whole machines, laser cutting parts, aluminum stamping, meter boxes, OEM metal boxes, angle brackets, etc. For stamping business, HY can design and manufacture new molds and respond to changes at a very fast speed, and can provide solutions for various difficult metal stamping parts.

Product Type: Angle Bracket, Corner Bracket

Surface Treatment: Galvanizing, Anodizing, Chrome Plating, Powder Plating

OEM/ODM: Support customization

Processing Technology: Mold, Stamping, Surface Treatment, Welding and Assembly

Send Inquiry

As one of the most common hardware, angle bracket (Corner Bracket) has a wide range of uses and many application scenarios, especially in the construction industry and home furnishing industry. The installation of tables, chairs, curtain walls, doors and windows, workbenches, wardrobes, etc. is mainly connected through angle brackets.

Angle bracket classification and common material selection

The selection of angle brackets is based on different application scenarios and needs. Different application scenarios have different stress conditions. The parameters that need to be confirmed for angle brackets include model, form and material type.

Just like other home decoration, in addition to pursuing practicality, it also pursues decorativeness. Choosing a suitable angle bracket can infinitely expand the home style.

Angle brackets can be roughly divided into the following types:

1. Shelf support angle bracket, a special connector used to connect and support shelves to ensure the stability and load-bearing capacity of the shelves.

Because they need to bear weight, most of them use high-strength materials, such as steel, aluminum alloy, etc., to ensure that steel brackets have sufficient load-bearing capacity and durability to ensure safety.

2. Door and window angle brackets are hardware accessories used to connect and fix door and window components. They are one of the indispensable hardware accessories in door and window installation. Since doors and windows face the natural environment all year round, load-bearing is not their main job. Preventing air leakage, water leakage, rust and sound insulation are the main requirements. Therefore, the materials are mostly lightweight, durable and corrosion-resistant alloys such as aluminum alloy and zinc alloy, thereby enhancing the strength and stability of the door and window structure, as well as the sealing and waterproof performance, extending the service life while also having certain shock absorption and sound insulation performance, and improving living comfort.

3. Furniture angle brackets are hardware accessories used for furniture assembly. They are mainly used for connecting furniture components such as table corners and cabinets. They require both structural strength and stability to ensure a safe living environment and reduce hidden dangers, and also have certain requirements for appearance. Furniture angle brackets are usually made of high-quality steel or stainless steel, and surface treatment, so that stainless steel angle brackets are beautiful, corrosion-resistant and load-bearing.

|

Materials |

Steel, aluminum alloy, zinc alloy, others |

|

Application scenarios |

Household appliances, electric heating tube components, switch accessories, auto spare parts, thermostat accessories, medical equipment hardware accessories. |

|

Process |

Stamping die, continuous die, stamping, tooling production, sample approval, CNC cutting, welding, bending forming, finishing |

|

Tolerance |

±0.03-0.05mm |

HY processing advantages

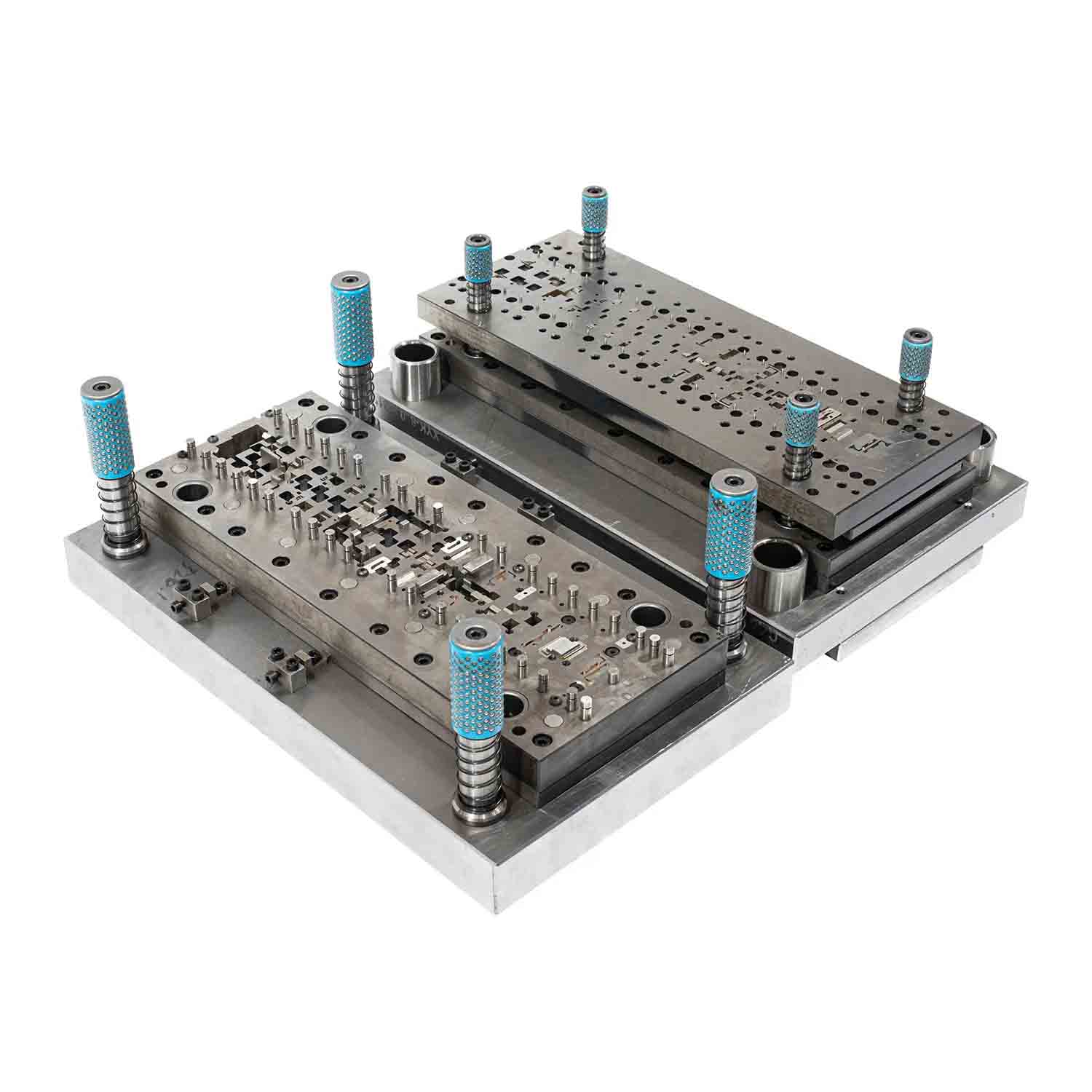

HY designs one-out-one, one-out-two, one-out-four, one-out-six or even one-out-eight production molds according to the order volume and production capacity. Whether it is large-scale or small-scale processing, continuous stamping processing can be achieved to meet the needs of production.

HY also continuously modifies and improves its own processes based on customer feedback to ensure that the stamping processing meets the order capacity while ensuring stable performance and suitable for long-term and efficient production.

And HY provides one-stop production services for angle brackets and heavy duty angle brackets, including mold design, cutting, stamping production, punching and tapping, surface treatment and after-sales. The stable performance is suitable for long-term and efficient production and guarantees user experience.

What products and services can HY provide

1. Architectural aluminum profiles, such as doors, windows, fences, screens, curtain walls, handrails, partitions, wardrobes, greening, solariums, etc.

2. Industrial aluminum profiles such as solar energy, LED, machinery, advertising, transportation, auto parts, display racks, telecommunications, etc.

3. Door and window systems, including sliding doors, side windows, tilt and turn windows, etc.

4. Processing, cutting, drilling, punching, milling, deburring, etc. of aluminum and stainless steel products.

5. As a professional foreign export company, we also provide engineering design, consulting, transportation and after-sales service.