China Outdoor Portable BBQ Grill Manufacturer Manufacturers, Suppliers, Factory

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Outdoor Portable BBQ Grill Manufacturer,Barbecue Grill,bbq grill stamping parts,outdoor grill,bbq grill,custom grill, We have exported to more than 40 countries and regions, which have gained fantastic popularity from our costumers everywhere in the globe.

Outdoor Portable BBQ Grill Manufacturer, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Hot Products

stainless steel lid

HY's stainless steel lid is a high-quality product made of high-quality 304 stainless steel. With its excellent strength and durability, it is ideal for sealing a variety of jars or bottles. HY's advanced stamping process ensures that the lid is seamless, well-formed and void-free, making it extremely corrosion-resistant. This production design makes it a versatile product that can be used in a wide range of applications from kitchen utensils to industrial containers.Stamping Photovoltaic Terminals

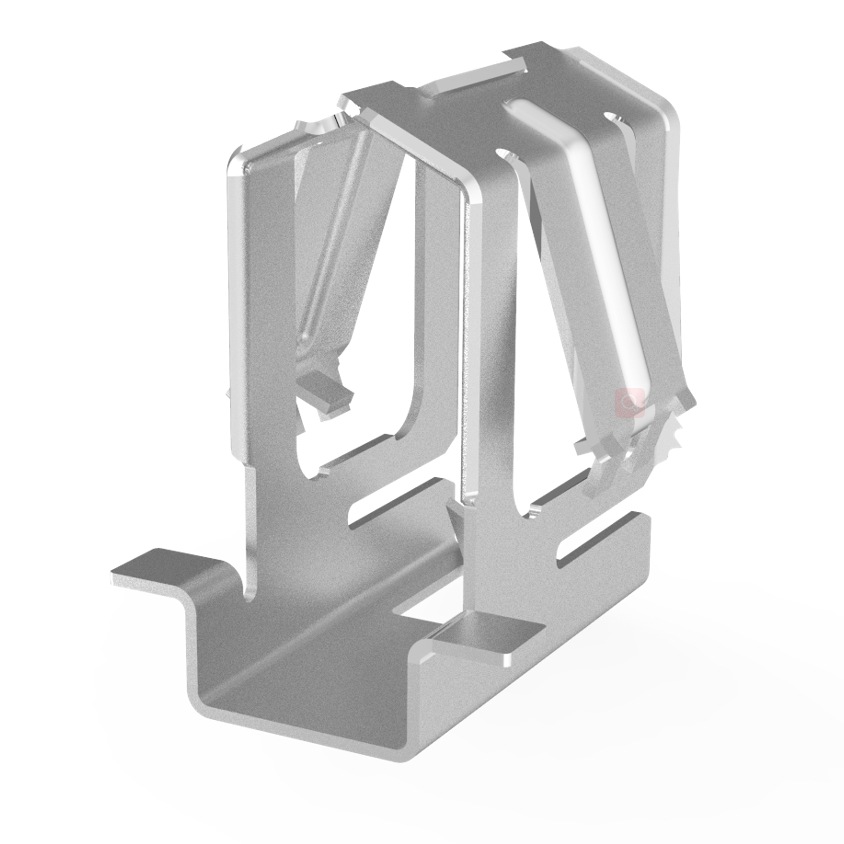

Welcome to wholesale Stamping Photovoltaic Terminals from us,every request from customers is being replied within 24 hours. HY is a factory that specializes in customizing the production of photovoltaic terminal .The photovoltaic terminals of a photovoltaic system inverter are vital electrical connectors used to establish connections between the inverter and the various components of the photovoltaic (PV) system. They play an important role in ensuring efficient and reliable power transmission within the system.Crimp Connectors

Xiamen Jiangjun Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Jiangjun's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precisionStamping Selective Plated Lead Frames

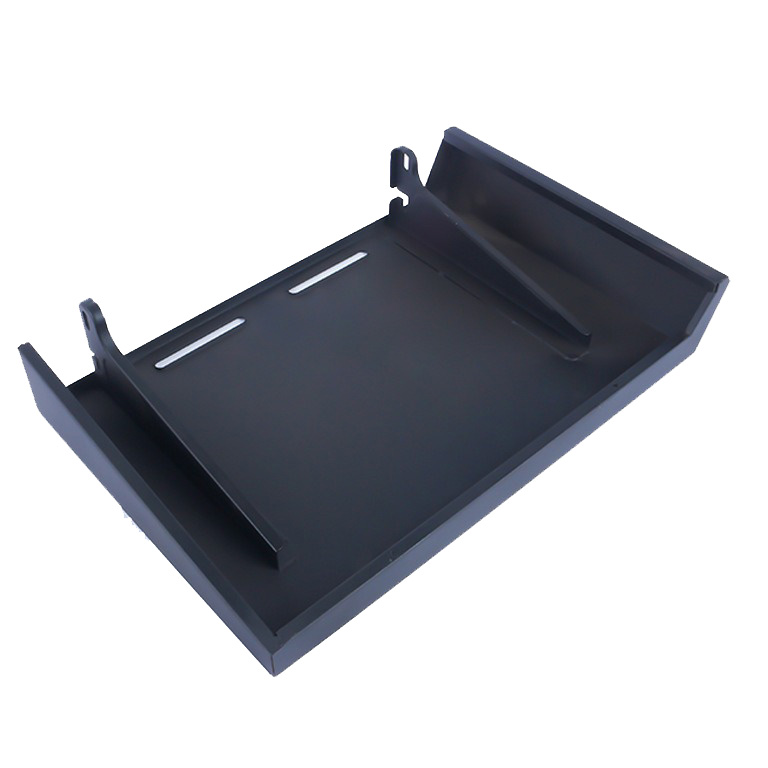

HY is a manufacturer and distributor of Stamping Selective Plated Lead Frames.HY utilizes stamping, plating and overmolding technologies to manufacture high-quality selective plated lead frames and precision components, providing hybrid solutions for sensor and power IC packaging.Gaming Keyboard

HY is a manufacturer of gaming mechanical keyboards. The stamped gaming keyboard produced is a high-end product specially designed for gamers, aiming to create the most accurate, comfortable and efficient gaming experience for players. Made with high-quality materials and advanced technology, this keyboard is both durable and high-performance.Aluminum Alloy Die Casting

Xiamen Jiangjun Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 days