China Mechanical main shell Manufacturers, Suppliers, Factory

Our organization sticks for the principle of "Quality will be the life of your business, and name may be the soul of it" for Mechanical main shell,car main shell,Automobile main casing manufacturer,Car main housing supplier,body shell, Leading the trend of this field is our persistent objective. Supplying first class solutions is our intention. To create a beautiful upcoming, we wish to cooperate with all close friends in the home and overseas. Should you have got any interest in our products and solutions, remember to never wait to call us.

Mechanical main shell, Strong infrastructure is the require of any organization. We have been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our merchandise worldwide. To maintain smooth work flow, we have now sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we're able to accomplish voluminous production without compromising upon the quality.

Hot Products

Casting Gearbox Components

Jiangjun Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.Casting Clutch Components

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a professional manufacturer of Casting Clutch Components, covering an area of 12,000 square meters, equipped with machining centers, gantry CNC lathes, laser cutting machines, CNC bending machines and other equipment. The company has more than 70 skilled engineers and professionals. Products are exported to more than 30 countries including the United States, Mexico, Spain, Norway, Morocco and South Korea.

Product Type: Casting Clutch Components

Size: Customization supported

Quality Control: 100% full inspection

Certification: ISO9001/CE/ROHS, IATFHeat Sink

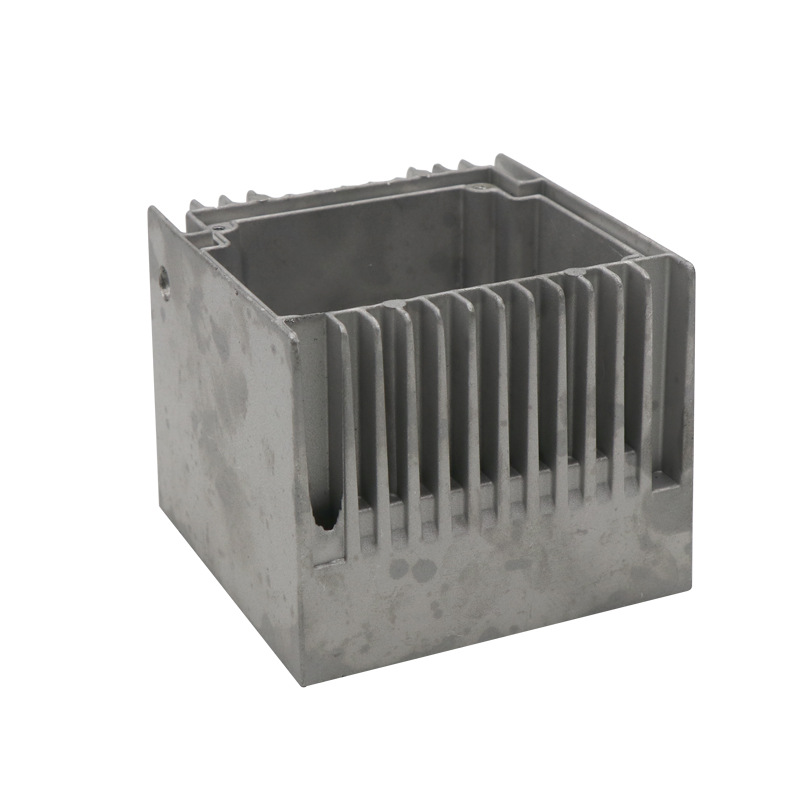

The Heat Sink produced by Xiamen Jiangjun Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum.

Material: 6000 series, such as alloy 6063/6061/6005, etc.

Shape: square, round, support customization

Color: silver, black, gold, champagne, support customization

Application scenarios: IC circuit boards, motherboards, transistors, etc.shower chair for disabled

Xiamen Jiangjun Intelligent Technology Co., Ltd. is a manufacturing company specializing in the production and sales of bathroom and medical care series products, with more than 17 years of processing experience. HY is proficient in global standards, focusing on the production of high-quality products, with a strict process system and quality inspection system to ensure product quality and delivery time. It has now covered the United States, Europe, Australia, the Middle East and other countries. We welcome global customers to establish cooperation.

Color: Black/Silver/White/Gray/Customized

Usage: Shower chair for disabled

Material: High-quality PE and thickened aluminum alloy pipe

Application scenarios: Bathroom, Hospital, OtherStainless steel flat washer

HY developed metal stamped stainless steel flat washers for customers in the medical industry. Made from 17-7 PH stainless steel, this stainless steel gasket has strong corrosion resistance and is not prone to rust, making it ideal for medical use.Mobile Phone Holder

Stamping mobile phone holder material specifications: aluminum, copper, stainless steel and other materials

Material characteristics: Comply with ROHS, SGS testing, Proofing time: about 3 days

Mold opening time: about one week

Mold type: continuous mold