China Stainless Steel Part Stamping Manufacturers, Suppliers, Factory

HY is a professional China Stainless Steel Part Stamping manufacturer and China Stainless Steel Part Stamping supplier. Stainless steel parts stamping is an important manufacturing process that is widely used in modern industrial production by processing stainless steel metal sheets into parts with certain shapes, sizes and precision requirements.

Stainless Steel Part Stamping has many advantages, the most important of which is that it can produce high-quality, high-precision parts, and has the characteristics of low cost, high production efficiency, and simple process. In addition, the stainless steel material itself has the characteristics of anti-corrosion, anti-oxidation, high temperature resistance, easy cleaning, etc., and can be used in many fields.

With the continuous development of technology and equipment, the application range of stainless steel parts stamping is becoming more and more extensive. It has become an essential process in many industries such as automobiles, home appliances, machinery, and electronics. Therefore, understanding the stainless steel parts stamping process and mastering the related technologies and equipment for stainless steel parts stamping will help enterprises improve production efficiency, reduce production costs, and improve product quality.

In short, stainless steel parts stamping is a very important manufacturing process, which brings many conveniences and development opportunities to modern industrial production. We should study and master this technology seriously to create a better future for the development of my country's manufacturing industry.

HY has established a complete quality assurance system and has successively passed ISO9001, TS16949, and ISO14001 system certifications, fully ensuring the stability and consistency of product quality. HY products are exported to the United States, Canada, Italy, France, Germany, Japan, Israel, South Korea and other regions.

- View as

stainless steel lid

HY's stainless steel lid is a high-quality product made of high-quality 304 stainless steel. With its excellent strength and durability, it is ideal for sealing a variety of jars or bottles. HY's advanced stamping process ensures that the lid is seamless, well-formed and void-free, making it extremely corrosion-resistant. This production design makes it a versatile product that can be used in a wide range of applications from kitchen utensils to industrial containers.

Read MoreSend InquiryMobile Phone Holder

Stamping mobile phone holder material specifications: aluminum, copper, stainless steel and other materials

Material characteristics: Comply with ROHS, SGS testing,

Proofing time: about 3 days

Mold opening time: about one week

Mold type: continuous mold

Stainless steel mixing bowl

Product name:Stainless Steel Mixing Bowls, Usage:Kitchen Home Hotel Restaurant, Logo:Customized Logo Acceptable, Production process: metal stamping,

Read MoreSend InquiryStainless steel flat washer

HY developed metal stamped stainless steel flat washers for customers in the medical industry. Made from 17-7 PH stainless steel, this stainless steel gasket has strong corrosion resistance and is not prone to rust, making it ideal for medical use.

Read MoreSend InquiryStamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing parts

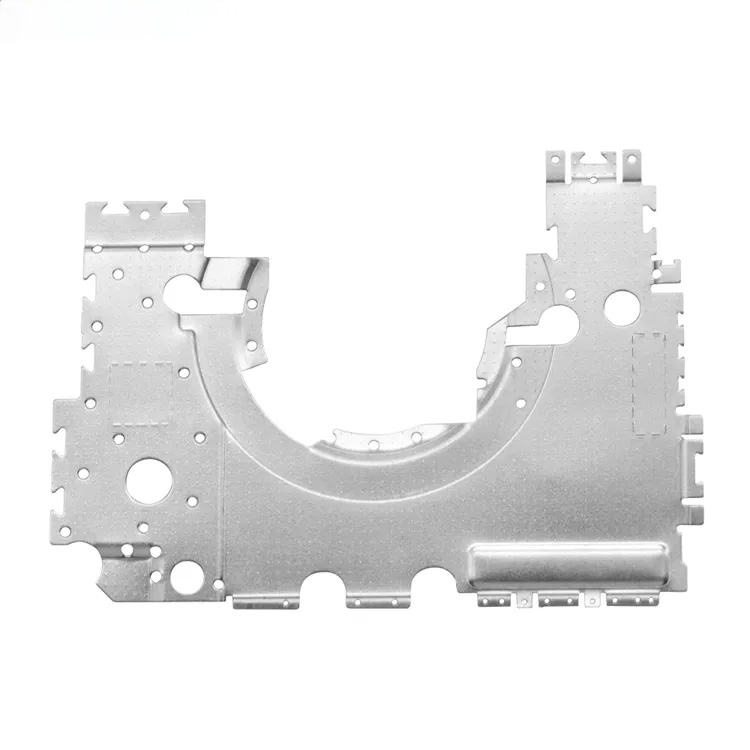

Read MoreSend InquiryMobile Phone Stainless Steel Stamping Parts

HY sixteen years of industry experience Material: SUS301 Mobile Phone Stainless Steel Stamping Parts specifications: customized according to customer requirements Material characteristics: complies with ROHS, SGS testing Qualification certification: ISO9001 & IATF16949

Read MoreSend Inquiry