Addressing Common Issues with Best Stamping Parts in Manufacturing Processes

In the rapidly evolving landscape of global manufacturing, stamping parts have emerged as crucial components that drive efficiency and precision in production processes. According to a report by the International Machine Tool Industry Association, the demand for high-quality stamping parts is anticipated to grow by 5.2% annually, reflecting the industry's increasing reliance on these components for effective manufacturing. As China continues to earn global respect for its manufacturing capabilities, emphasized by its recent achievement of producing over over 28% of the world's industrial goods, the quality of stamping parts plays a vital role in maintaining competitive advantages.

This blog will address common challenges faced in manufacturing processes involving stamping parts and provide insights into best practices that can enhance overall product quality, thereby ensuring that Chinese manufacturing remains synonymous with excellence and reliability in the eyes of the world.

Common Challenges in Stamping Parts Manufacturing

In the realm of stamped parts manufacturing, various challenges arise that can hinder efficiency and quality. One significant issue is the material selection, as using subpar materials can lead to defects and insufficient strength. For instance, the rising interest in innovative materials, such as shaped wire, highlights the need for manufacturers to adopt advanced materials that enhance the performance of stamped parts. These innovations not only optimize the stamping process but also contribute to the lightweighting efforts essential in modern automotive design.

Moreover, automation in manufacturing processes presents both opportunities and challenges. The implementation of automated bin-picking systems is revolutionizing the way manufacturers handle parts. Although these technologies can significantly reduce human error and improve efficiency, they require substantial investment and training, posing a challenge for small to medium enterprises. As the industry evolves, staying ahead of technological advancements and material innovation is crucial for overcoming these common manufacturing obstacles and ensuring the production of high-quality stamped components.

Addressing Common Issues with Best Stamping Parts in Manufacturing Processes - Common Challenges in Stamping Parts Manufacturing

| Challenge | Description | Impact on Production | Potential Solutions |

|---|---|---|---|

| Material Quality | Inconsistent material properties leading to variations in stamping. | Increases scrap rates and reduces overall quality. | Establish strict material specifications and supplier audits. |

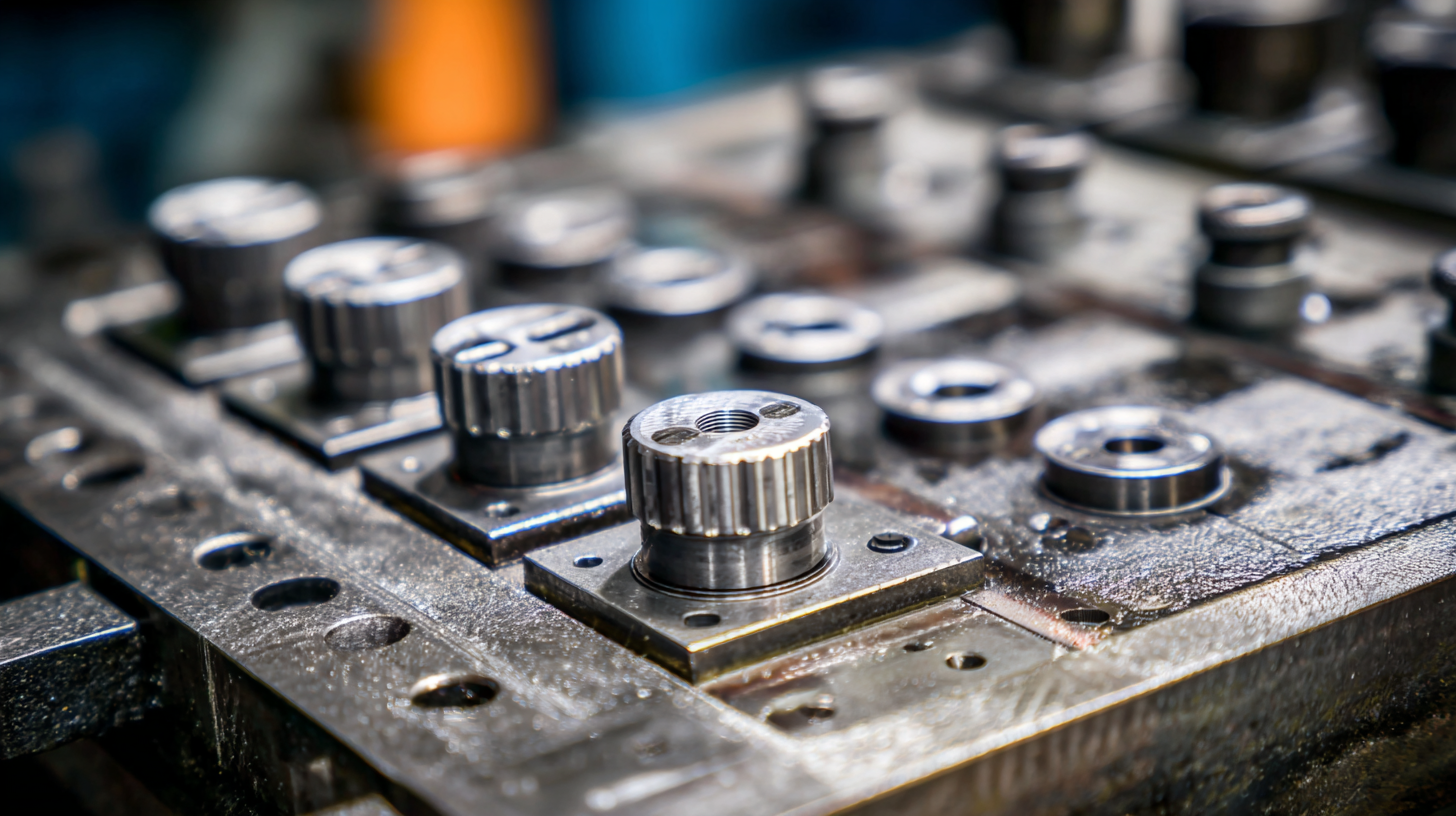

| Die Wear | Deterioration of dies over time affecting part dimensions. | Leads to precision issues and rejects. | Regular maintenance and timely replacement of dies. |

| Alignment Issues | Misalignment during the stamping process causing part defects. | Results in increased rework and longer lead times. | Implement precision alignment tools and regular checks. |

| Lubrication Problems | Inadequate lubrication leading to increased friction and wear. | Can cause die damage and defects in parts. | Optimize lubrication process and regular monitoring. |

| Operator Training | Insufficient training leading to improper handling of machinery. | Increased risk of accidents and production errors. | Implement comprehensive training programs for operators. |

Identifying Quality Issues in Stamped Components

When it comes to stamped components, ensuring quality is a paramount concern in manufacturing processes. Identifying quality issues early on can save significant costs and enhance overall production efficiency. Common problems such as inconsistent material thickness, inadequate die alignment, and surface imperfections often arise during the stamping process. These issues can lead to defective parts, which may not only compromise the performance of the final product but also result in increased scrap rates and delays.

To effectively address these quality concerns, manufacturers must implement rigorous inspection protocols. Using advanced measurement tools and techniques, such as laser scanning and dimensional analysis, helps in detecting deviations from specifications. Additionally, investing in employee training and fostering a culture of quality can empower workers to recognize potential issues before they escalate.

By prioritizing quality in the stamped components, manufacturers can ensure reliability, reduce waste, and ultimately deliver superior products to their clients.

Best Practices for Improving Stamping Process Efficiency

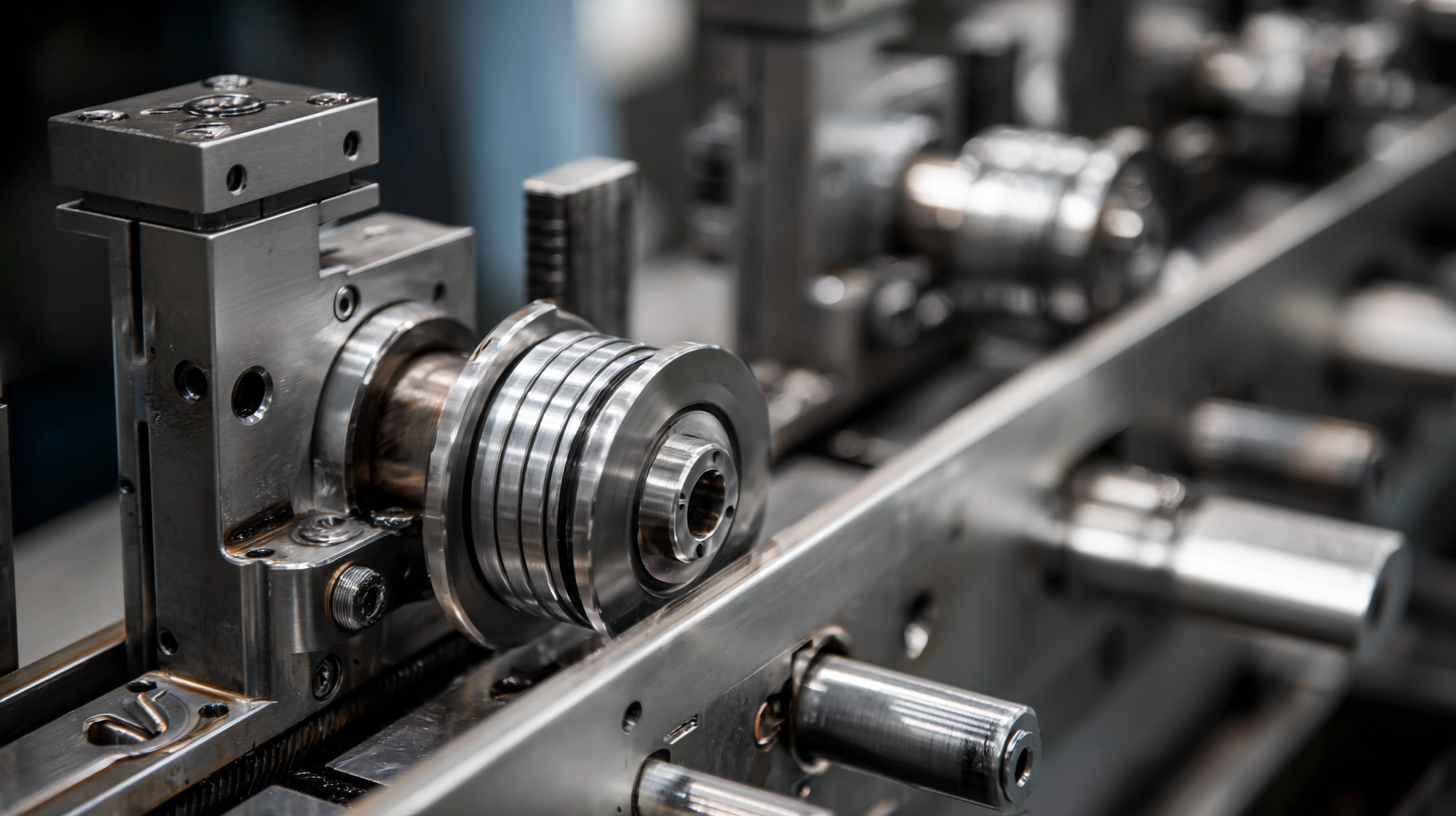

In the world of manufacturing, efficiency in the stamping process is crucial for both productivity and quality. One best practice to enhance this efficiency is to invest in state-of-the-art stamping technology. Utilizing advanced machinery with automation capabilities can significantly reduce cycle times and enhance precision. This technology allows for quicker setups and less downtime, enabling manufacturers to meet high-demand production schedules without sacrificing quality.

In the world of manufacturing, efficiency in the stamping process is crucial for both productivity and quality. One best practice to enhance this efficiency is to invest in state-of-the-art stamping technology. Utilizing advanced machinery with automation capabilities can significantly reduce cycle times and enhance precision. This technology allows for quicker setups and less downtime, enabling manufacturers to meet high-demand production schedules without sacrificing quality.

Another important aspect is the training and skill development of operators. Ensuring that staff are well-trained on both the machines and the materials used can lead to better decision-making on the shop floor. Regular training sessions can help operators identify potential issues early and implement corrective actions promptly, minimizing waste and rework. Implementing a culture of continuous improvement encourages employees to share their insights and suggest innovations that could streamline operations even further. By focusing on technology and personnel development, manufacturers can achieve remarkable improvements in the efficiency of their stamping processes.

Material Selection and Its Impact on Stamped Parts Quality

Material selection plays a crucial role in determining the quality of stamped parts in manufacturing processes. Different materials exhibit varied properties, such as

strength,

ductility, and

corrosion resistance, which directly influence the performance and durability of the final product. For example, choosing

high-strength steel over aluminum can enhance the structural integrity of parts designed for automotive applications, where

safety and

reliability are paramount. Conversely, materials with lower strength but higher machinability, like softer metals, may be favored in applications where precise shapes and reduced weight are more critical.

Material selection plays a crucial role in determining the quality of stamped parts in manufacturing processes. Different materials exhibit varied properties, such as

strength,

ductility, and

corrosion resistance, which directly influence the performance and durability of the final product. For example, choosing

high-strength steel over aluminum can enhance the structural integrity of parts designed for automotive applications, where

safety and

reliability are paramount. Conversely, materials with lower strength but higher machinability, like softer metals, may be favored in applications where precise shapes and reduced weight are more critical.

Moreover, the compatibility of materials with stamping processes is vital in achieving optimal results. Certain materials may require specific techniques or tooling to ensure accurate and efficient production. The grain structure and thickness of the material can significantly affect the stamping process; for instance, thicker materials may necessitate higher force and precision in die design to avoid defects. By carefully selecting the right material and understanding how it interacts with the manufacturing process, manufacturers can significantly reduce the likelihood of defects, improve yield rates, and enhance the overall quality of stamped components.

Technological Innovations in Stamping for Enhanced Performance

Technological innovations in stamping processes have significantly transformed the manufacturing landscape, enhancing both efficiency and performance. According to a report by Grand View Research, the global metal stamping market size is expected to reach $371.88 billion by 2025, growing at a CAGR of 4.2%. This growth illustrates the increasing adoption of advanced stamping technologies that streamline production and reduce operational costs.

One of the key advancements in stamping technology is the integration of automation and robotics. These technologies not only optimize the stamping process but also minimize human error, which historically has affected production quality. A study published in the Journal of Manufacturing Science and Engineering highlights that automated stamping systems can boost productivity by up to 30% while improving precision and consistency. Additionally, developments in tooling materials and design have enabled manufacturers to create parts with intricate geometries and tighter tolerances, meeting the rising demands for complex components in industries such as automotive and aerospace.

Furthermore, the incorporation of Industry 4.0 principles and smart manufacturing techniques empowers stamping facilities to utilize real-time data analytics for predictive maintenance and process optimization. According to a market analysis from MarketsandMarkets, the smart manufacturing market is projected to grow from $214.7 billion in 2017 to $384.8 billion by 2025, underscoring the importance of integrating IoT and data-driven solutions in modern stamping operations. These innovations not only enhance overall performance but also ensure that manufacturers can swiftly adapt to changing market dynamics, driving a competitive edge in the industry.